64studeavanti

AOAI Forum Members-

Posts

600 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by 64studeavanti

-

AFAIK modern tires have a short life, maybe 5 years. I have a set of BFG, 205R15, on one of the Avantis, maybe 12 years old, always in garage, they have cracked sidewalls. I also have a set of Coker Bias tires, 6.70x15. They are about the same age and still look good. Bought some Coker American Classic, 670R15, last year. Too soon to tell how they hold up.

-

Both R5408, 4spd with A/C, and R5423, Auto with A/C, have the cooling kit that ducts air from the cowl vents to the transmission tunnel installed. Of course, both could have been modified after production.

-

Do later Avantis have the Studebaker transmission cooling fix? In a service bulletin, Studebaker specified a kit that was installed where cool air from the cowl vents was ducted to the transmission.

-

Studebaker Avantis are only 63 and 64 year models. One of the items are the door catches made by Mercedes. I discounted the disk brake pistons as they were made by Bendix under license from Dunlop. Maybe count the ball bearings in the super charger. I believe they were made in Germany.

-

Working on R5423. I have removed the undercoating. In some spots, the fiberglass is very dry/porous and somewhat brittle. Any ideas on how to remedy? I have used penetrating expoxes, such as those from West systems, on plywood before. Should I do something similar? Leave it alone and coat with epoxy primer? I plan on reapplying the rubberized undercoat, 3M Dynatron Dyna-Pro, similar to the factory, to protect the fenders and other parts of the underbody from rocks etc. Any ideas welcome. thanks

-

What Brake Booster can be used on a '63' - '71' Avanti?

64studeavanti replied to aardvark's topic in Avanti Trivia

There have been suggestions on this forum that an 8" booster from a 60-70 mopar b body will work. There is also a post on this forum in the trivia section that indicates an 8 3/4" mopar hemi booster is the same. I asked on this forum, and did not get a definitive answer. https://aoai.org/forums/topic/43007-wanted-avanti-brake-booster-1963-1971/#comment-126070 In any case, I have dealt with Bob Ziff at Avanti Parts and Restorations and he is a stand up guy. -

-

check to see if this tube runs alongside the fuel line. if so, likely the fuel return line. most 63s had a special "T" from the outlet side of the fuel pump that returned some of the fuel to the tank. later cars had a fuel filter with a glass bowl that provided the same function.

-

where are you located?

-

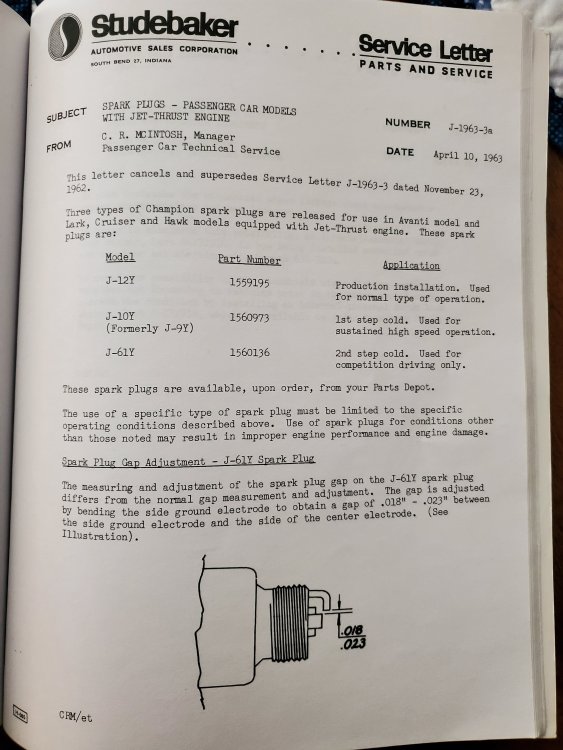

J12YC has Copper core. I believe current plug is RJ12YC. if you use resistor plugs do not use resistance wires.

-

workshop manual specifies J9Y, however, service letter updates this to J12Y with J10Y being one step colder as Dwight states.

-

Fair value for this '63 avanti in need of restoration?

64studeavanti replied to OpenRoad's topic in 1963-64 Avanti

I purchased a 64 R1, with A/C and auto, last fall for $4500. This car spent its life in Florida so frame, hog troughs etc were in great condition. It was apart, but complete, with a claimed rebuilt engine and transmission. There were many new parts in boxes including parking lamp assemblies, body rubber gasket set and dash pad. Your hog troughs seem to be ok, but the frame sure looks crusty. -

I purchased them in Jan 2022 for $1332 including shipping to FL. The ones he is selling are one piece galvanized. Had to cut away more of the body than I would prefer, but they fit well.

-

Do not have email address for him. However, phone is 865 908 6100 and address is: 1081 Rule Hollow Rd Sevierville TN 37876. I purchased some hog troughs from him a couple of years ago.

-

Thanks, looks similar to the earlier ones. The improvements must be hidden.

-

Service bulletin F-1963-17 specifies improved headlining. Since neither of my 64s have original headlining, does any one have pictures or description of the improved version?

-

It is simple, any 12v stude V8 starter will work as long as it correct for the transmission. Early Avantis had 3 Pole Prestolite starters same as Hawks and Larks. There was a service bulletin on May 9th, 1963 that specified a change to 4 Pole. FWIW, my 64 R1 came to me with a Delco starter and it worked fine

-

What is a 2001-7 Avanti called?

64studeavanti replied to aardvark's topic in 2001-2007 Avanti models

There is a registry at theavanti.com I also recall that there is one on Bob johnstones web site. -

The prior years Studebaker Delco starter will work. Just make sure you get one for the transmission you have. Manual vs automatic are different.

-

Actually, boosters for hemi equipped cars are larger. They are 8 3/4", similar to our Avantis, as opposed to the smaller 8" non-hemi Mopar. The hemi equipped cars have an offset bracket etc. to clear the heads.

-

Sorry I was not clear. There have been some conflicting information about whether B body Mopar brake boosters are a replacement for the Stude ones. In the trivia section, it was stated that the "hemi" equipped cars used the same 8 3/4" brake booster. This booster, like Avanti boosters, are hard to come by. In a later post on this forum, it was claimed that the readily available 8" Mopar booster works. Most of the posts on the Mopar forums indicate that the hemi boosters are not interchangeable with other mopars and versa visa. Just trying to find out if the readily available B body 8" Mopar boosters work on Avantis.

-

So master cylinder is good. What about booster?

-

Here is a link to previous discussions: https://aoai.org/forums/topic/43007-wanted-avanti-brake-booster-1963-1971/#comment-126070

-

Nelson, please post results. I have been trying to get a definitive answer. So far, just 3 or so threads on how they are the same with no one actually trying one. As Bob pointed out, the mopar ones are different size.

-

Check plate 11-3 in the parts manual. 1107-33 is the reference. One end attaches to one of the caliper bolts. The other end is for the hose/pipe.