64studeavanti

AOAI Forum Members-

Posts

678 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by 64studeavanti

-

back up. saw that Dwight posted at 5:55.

-

saw that also when I navigated from the main website.

-

-

same here. I think it started having issues yesterday.

-

I bought a 64 Avanti project at an auction a little over a year ago for $4500. R1 with A/C and auto. Engine and transmission supposed to be rebuilt. Came with extras such as new dash pad, rubber kit, etc.

-

Just thinking out loud, has anyone tried to adapt a/c from a hybrid or full EV car?

-

How much is a supercharger setup worth?

64studeavanti replied to Ronny Daytona's topic in 1963-64 Avanti

Not that it matters, but I have R5408, R1 with A/C and 4spd. One of 23 built in 64. Gold with Elk interior. Currently getting ready for paint. -

How much is a supercharger setup worth?

64studeavanti replied to Ronny Daytona's topic in 1963-64 Avanti

Think we scared Ronny (O.P.) away. -

How much is a supercharger setup worth?

64studeavanti replied to Ronny Daytona's topic in 1963-64 Avanti

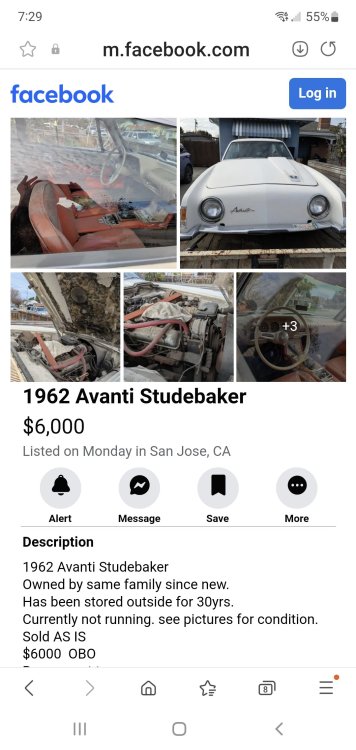

Someone with a Facebook account could ask some questions to get clarification as to color of interior, transmission, and whether there are any other parts. -

How much is a supercharger setup worth?

64studeavanti replied to Ronny Daytona's topic in 1963-64 Avanti

Looks more like orange to me. Could be the rare "Creamsicle". -

How much is a supercharger setup worth?

64studeavanti replied to Ronny Daytona's topic in 1963-64 Avanti

Just guessing this is the car since he previously asked about a 62. This is advertised as a 62 sitting outside for 30yrs. -

How much is a supercharger setup worth?

64studeavanti replied to Ronny Daytona's topic in 1963-64 Avanti

This may not be the car in the original question. The car pix I posted from Facebook has no text indicating 4 Spd. Let's hear from OP as to whether this is the car or not. -

How much is a supercharger setup worth?

64studeavanti replied to Ronny Daytona's topic in 1963-64 Avanti

This is not a 4spd. Notice the yellow dipstick for the auto trans in the engine bay. -

How much is a supercharger setup worth?

64studeavanti replied to Ronny Daytona's topic in 1963-64 Avanti

-

Been working on this car off and on for 5 years. Body is bare and on rotisserie. Glass, trim, interior etc has been removed. Frame has been media blasted and painted. Engine, transmission, and suspension have been rebuilt. All parts are NOS or excellent used. Hog troughs have been replaced. The undercoat on the body was removed and fresh was reapplied. Hopefully, this is the last push to get it in color and start the reassembly. The plan is to wind up with a brand new 60 year old car! Agreed on the powder guide coat. Works much better than the spray.

-

This is the first fiberglass car I have prepped for paint. On metal cars, I can fix most of the problems with a hammer and dolly, shrink, or stretch as needed. On this car, all I can do is add more filler to straighten the panels. When I redid the bad body work, I used resin, mat, and kitty hair so those areas are structurally sound.

-

I have 2 63s and 2 64s with A/C. They all have the same heavy cast iron pulleys as R2. Strange thing, the aluminum pulley, 1563110, is listed in the December 63 parts catalog. I have R5408 and R5423. R5408 was completed December 2nd.

-

I figure I have about three weeks to get it into primer. I should have a couple of weeks to finish block sand. I will have help mounting the body. Mounting the body, hanging the doors, hood and trunk lid should only take a day or two. The heavy body work is done, all I need to do is skim and true up the filler. The Ultra Extra helps quite a bit as it gives me a much longer work time and sands very easily. Doors, hood and trunk lid are in pretty good shape, at least according to the guide coat. I plan on doing a "scuff and puff", no block sanding, in the engine bay and trunk as well as the back side of the hood and trunk lid.

-

The R1 pulleys are the same as R2. The aluminum water pump pulley, 1563110 became available with an improved idle cooling kit announced in service letter R-1964-4, dated April 24, 1964.

-

As one of the Corvette Forum posters stated, "I will keep working it until my give a s... bucket is empty". I do have a deadline. It is scheduled in the paint shop the middle of April. If I miss that date, it will be several months before I can get another. I still have to complete body work, assemble the body (doors, hood, trunk), mount it back on the frame, prime, and block sand. Wish me lots of luck! This car was quite a mess. It supposedly had a "professional" paint job when I bought it 20 years ago. The driver door had a new skin over a destroyed frame. The hood had a hole cut in it that was improperly patched. The hood brace was installed on the driver side, the firewall was a disaster, evidence of lots of poor work done to the front fender, etc. I was able to source a different door and hood. and have been able to repair most of the shoddy body work.

-

Prepping a 64 for paint. Working on the roof as that is the 'flattest' panel. I am surprised at how wavy it is. I stripped it down to original primer using razor blades. I then used a long board to remove the primer so I would not create any new waves. Several low spots are identified using the original primer as a guide coat. In order to get the roof straight, I had to skim coat the entire surface. Are the waves the way the car came from the factory? I have nothing to gauge this as I have never worked on an Avanti or other fiberglass car. If a metal car was that wavy, I would do more metal work. The car did have at least 2 repaints based on the layers I stripped off. FWIW, I am using a 50-50 mix of Rage Ultra and Rage Ultra Extra to extend work times. It does have longer work time, and of course, longer cure time.

-

Automatic to 4 or 5 speed conversion in a 63Avanti

64studeavanti replied to rhusak's topic in 1963-64 Avanti

Nothing -

Automatic to 4 or 5 speed conversion in a 63Avanti

64studeavanti replied to rhusak's topic in 1963-64 Avanti

Yes, I have a 63, and a 64 automatic. They have the same frame mount as my 64 4spd. -

I have been told that if you are spraying metallic, which most Avanti colors are, it is better to spray everything at once to maintain a consistent pattern. Here is a pic of the window channel of a car I am prepping for paint that shows a similar gap between the lower frame and A pillar. This car had quite a bit of bedding compound.

-

Check with the paint shop. The guy I use prefers that the car be assembled with doors, hood and trunk. He charges extra if it is apart. FWIW, the factory painted the door, hood, and trunk hinges the same color as the body.