Avanti83

-

Posts

1,282 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Avanti83

-

-

If it indeed is leather then contact Leatherque http://www.leatherique.com/, they have excellent products and should be able to discuss your needs. I used their products on my 83 with excellent results. Vinyl takes entirely different technology. Bob

-

I am in the process of taking out the engine of my 63 so I can have the engine compartment painted. I removed the wiper motor and found that it is bolted on with nuts that are under the mounting and are now somewhere down in the fan motor or somewhere else under the dash. It looks like i have to go on a mission of taking apart the pieces under the dash to reinstall the motor when the painting is complete. Any thoughts on this issue?

If you want to put it back with the nuts in place, you could weld them in position but unwanting to do that, use Gorilla glue or other adhesive to hold them in place.

-

RQB3263....IM GITTIN IN KINDA LATE HERE BUT...JOHN MEYER, DUNCAN FALLS OHIO (MEYERS STUDEBAKER) ENLIGHTENED ME ON THE 400CID INSTALLATIONS...IT SEAMS THAT BECAUSE THE 400 IS A TORQUERER ENGINE THAN THE 305 THEY SOMETIMES HAVE CRACKED THE FRAME AT THE ENGINE MOUNT SUPPORT POINTS.....REPAIRING WITH THE ENGINE IN THE CAR IS ALMOST IMPOSSIBLE...JOHN CAN SUPPLY YOU WITH A DRILLED ENGINE MOUNT REINFORCEMENT PLATE TO INSTALL WITH THE ENGINE OUT....ITS A WELD IN DEAL I BELIEVE....REALLY SOUNDS LIKE A GOOD IDEA TO ME....MYERS ADVERTISES IN THE AOAI MAG AND ARE GREAT FOLKS....BILL RQB3263

Bill is correct about the difficulty in repairing the frame with the engine in the car but the problem with the frame can happen with a 350 also. My 74 400 SBC was replace with a 350 by Nate Altman shortly after the OP made the purchase. The frame still cracked. It is caused buy the factory that quit putting washers on the bolts that hold the motor mounts to the frame which then point loaded the frame with bad consequences. The 400 will exacerbate the problem but everybody should be checking their installations at some point.

This is some of the damage. I repaired it with a complete reweld of the cracks and a plate underneath spanning the cracked area. I don't need the 383 recracking the frame.

-

Corvettes tend to mount most accessories low on the engine for hood clearance, I'll bet about any other models bracket should work. If Warren has one, he could send you a picture. Don't forget that on most power steering brackets there is generally a brace that goes to the block also. I'll bet his works. Otherwise you'll need to find one. Ebay used to be a good place but those type of things are getting harder to find. I probably also have one but won't be able to access my storage for a week or so. If you have swap meets close by, I'll bet you can find a few.

As an aside, if you change pumps you will probably need to replace the reservoir on the new one with the one on your current pump as the one outlet position is important. It's an easy job.

-

Just for the record, I know the answer should be true, but as with all of these open ended questions there are scenarios that would make it false and it only takes one instance to do so. Bob

-

If it not overheating I'll say yes it will run cooler false

-

(SOB) Have you checked to see if you will have to realign the front end or have you already done that?

thx

SS

It still needs to be realigned. I've just set it close for rolling around. Luckily there is an alignment shop locally that know old kingpin setups and does an excellent job on them. Bob

-

A good friend of mine has a 63/64 OEM grill for sale

He's asking $200 plus shipping. If interested I'll supply either phone or email address. Bob

-

Brad makes a very good point. Soooooo, if you have an interest in the Watsons Street Rod LED's, but not sure they will fit, ( Ithink they will ), I'd call Watson's and ask if they have a non functioning LED headlight that you could "borrow" for the cost of the outbound and return shipping, to test fit. The worst they can say is no.

John

Excellent idea, I hope it pans out as I'm interested in those headlights also. Bob

-

I'm curious as to the engineering idea of going with a 2" inlet and a 1 3/4" outlet on the mufflers. Be it ever so slight, but there's still a reduction of 1/4" of pipe diameter that's going to slow the flow down, or is this a "venturi" effect where the air and exhaust hitting a restriction actually speeds up passing through the restriction??

Any time you reduce the cross section the flow must go up under standard conditions, what goes in must come out.

Remember that the muffler is probably a cooling area also so it's probably close to a wash.

-

I have an entire dash(both inner & outer) I'd like to sell (raising money for a paint job) if interested call501-590-9375.

Posting pictures for Dave of his dash.

-

Found a 60 psi sender if that's your gauge range. Bob

-

I would like to know all the specifications for the front coil springs. I have a '78 that needs new springs. Moog cc655 were given as replacement springs. Is that correct? I looked up some specs on the cc655 and the free height was given as 13.63" The springs I have are 15.43" sitting out of the car.

I need to know what you guys have used. Being in New Zealand makes bringing coil springs in a very expensive option. If I have the specs something for a larger car here may fit. I'm no expert on the "black science" of coils

Cheers

Mike

CC655 springs on my 74. It obviously hasn't been driven so I would expect some settling as it will have more weight on it after the hood and interior are added. The aluminum spacers were removed. They are generally the "go to" inexpensive coil replacement for most Studebakers and derivatives. I believe they are Buick rear springs but can't recall the years exactly. Search CC655 on the SDC forum should give you a ton of info.

The tires are 225/55/R17 for reference. Bob

-

RQB3263....While visiting Classic Cars Inc. (Avanti IRS &IFS specialists) in Gainesville, Fl. I was shown a set of Mazdz Miata seats that would appear to be close to a direct bolt in in the Avanti...They would certainly be something to look at after all the work i went to to install the BMW 330 seats...In fact i may switch out the BMW seats for miata someday ...RQB3263....BILL

Bill

You may be on to something good here. I just looked at Ebay after reading your post and found that the 2006 and newer seats mount very much like the OEM Avanti. This is a shot of the adapter plate to put other seats in a Miata but it clearly shows the mounting configuration that would be found on the 2006 and up OEM Miata seats. Depending on bracket spacing they are very close.

Good Find.

-

I would suspect so, it looks like the SW senders in my Avantis. Their return policy is second to none. Bob

-

I confuse easily, is the sender the original that came with your car. If so, then it should work. If a replacement sender then the odds are pretty good that it is just a grounding sender that turns on the idiot light.

Go to Summit Racing and match the SW sender PSI to your gauge and you should be good to go. Bob

-

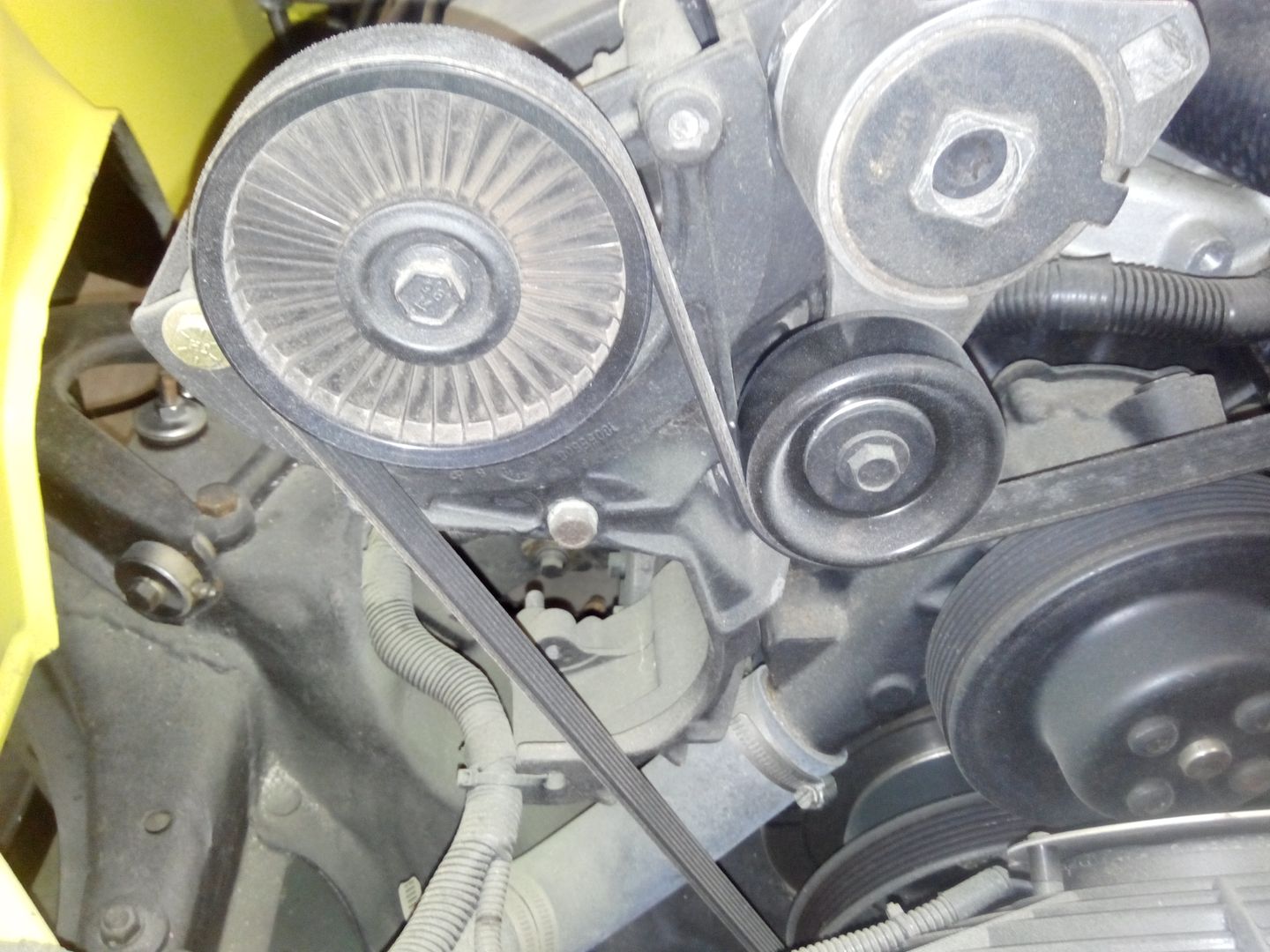

Warren is correct about the serpentine belt, they came into being much later than 73. I have a Camaro 91ish setup on my 74 SBC and the pump is not installed. Just need the correct belt length.

I don't have a head on shot but could get one if necessary.

Had the phone in the PB yesterday, so here's a shot of the engine front.

-

On a whim I Googled 1970 cars with Dana 44 and found that the Ford Bronco had a 44. Rock Auto says they have 11" rear brakes and there are pictures so maybe something helpful there. I would think a lot of that era Dana 44's would use the same axle.

-

The original owner of my 74 Avanti had it until he sold it to me in 2012, so 38 years for him. It was his everyday driver and boat hauler for many years before he parked it. He was from the Detroit area, purchased it new from Nate Altman, had him replace the 400 SBC with a 350 and it was serviced by Dan Booth of Nostalgic Motors, Wixom, Mi. Original 4-speed. If all that counts.

-

Bob Johnstone's site says http://www.studebaker-info.org/Avanti/avtext3/RQBrearbrakes.txt

69 - 72 Plymouth Fury.

-

two fans one motor IIRC so false

-

I know there are a couple of body folks on the forum, my question: For a home builder, why wouldn't it be easier to just add a plastic panel to the underside of the roof supported by curved ribs to hold the roof profile, and after tapering the opening, fill the opening with mat and finally a layer or two of cloth. Then just remove the ribs and plastic panel. That would not require the formidable removal of all the underside trim/headliner and only leave the old opening requiring a filler headliner panel. Bonding a complete roof assembly would not be for the faint of heart either.

-

I'll say yes it will fit and function. While I'm not sure of inlet/outlet size differences, that's a minor difference to function.

-

How does that work?

Always like your input Bob.

Thanks Gene

You need to open the ID of the bearing race so it just slides on to the shaft instead of being a press fit. That way they just slide off instead of needing to be pressed on every time you need to change the shims. Learned it from an old local chaps that is a Wiz with rear ends and trannys. Most of the local racers use his talent. Bob

Engine stand

in 1963-64 Avanti

Posted

As MFG says above, with the weight being further from the base, you would not only need a support but also one of the better stands that has dual wheels on both ends so the stand is less prone to tipping. Remember that moving that amount of weight further from the mount adds a lot more torque to the mounting arm. It you chose to do it, be darn careful. Bob