-

Posts

294 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by ronmanfredi

-

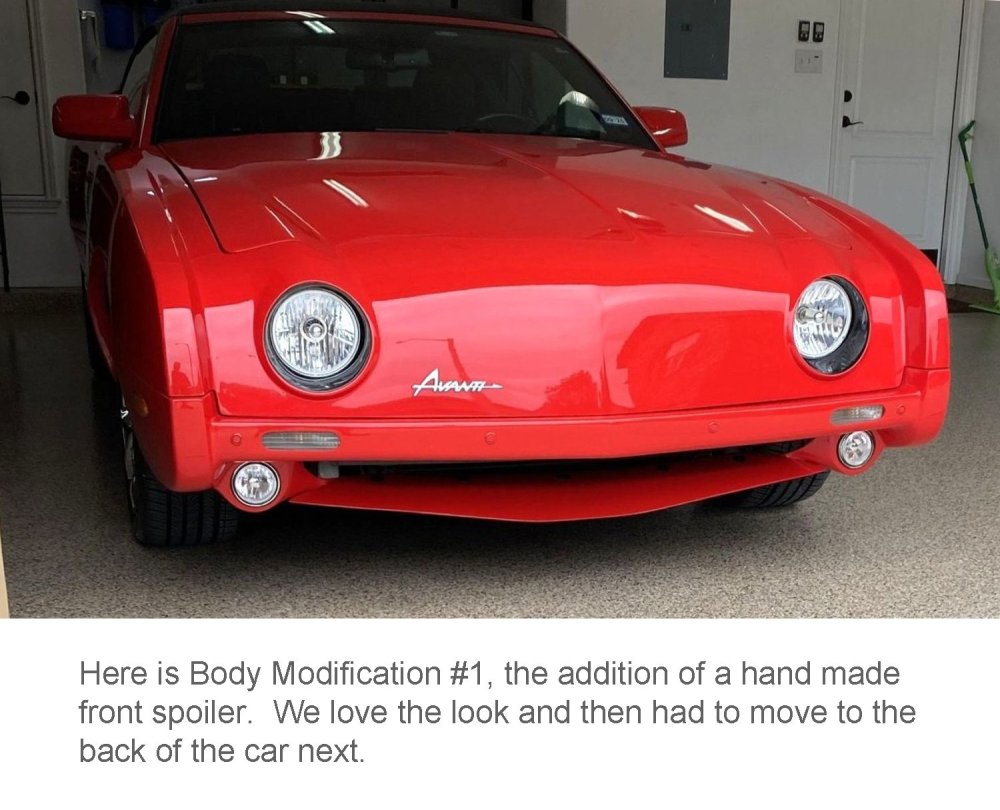

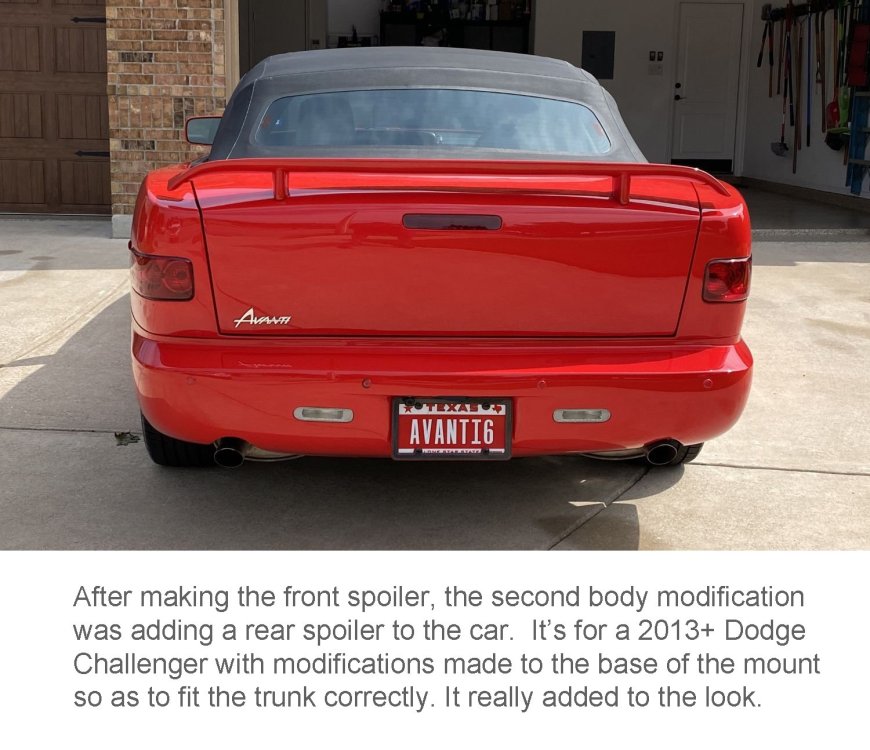

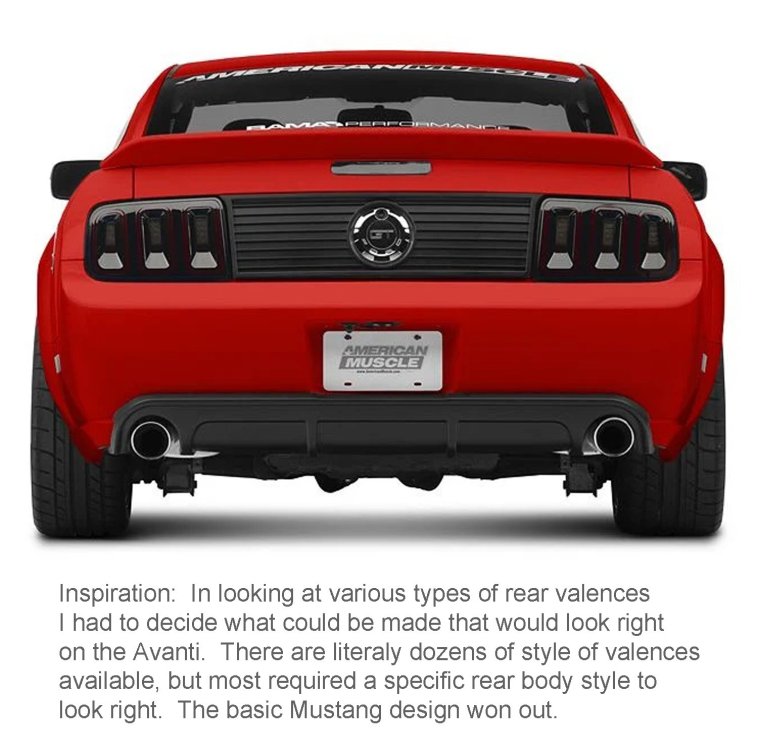

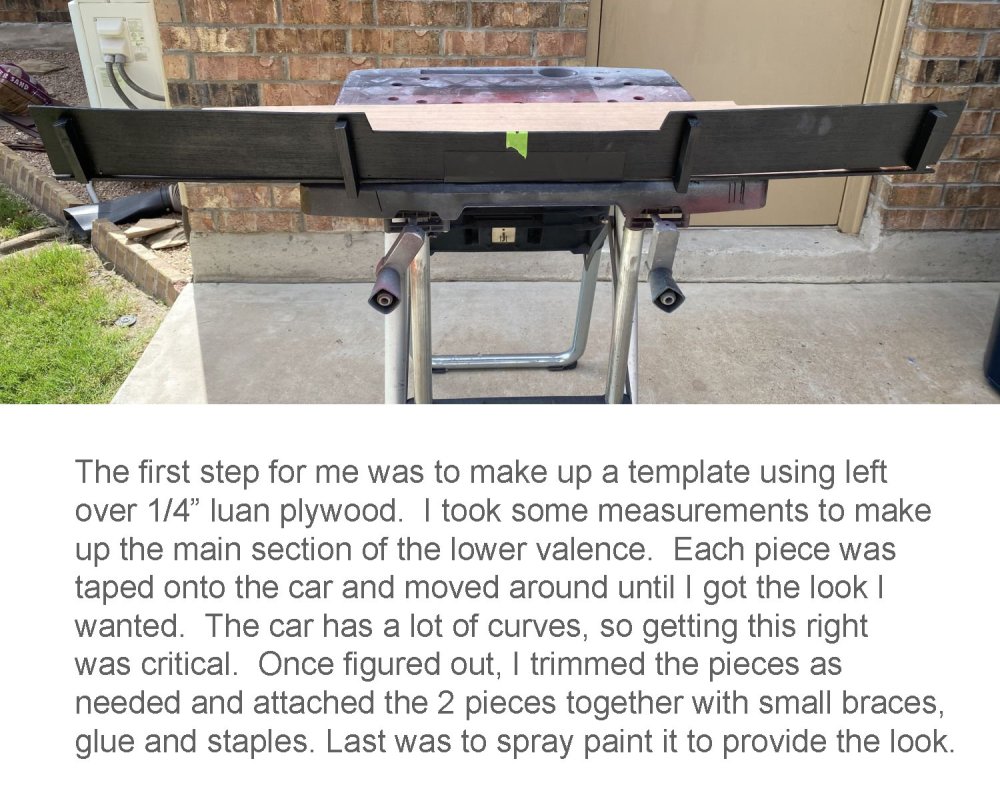

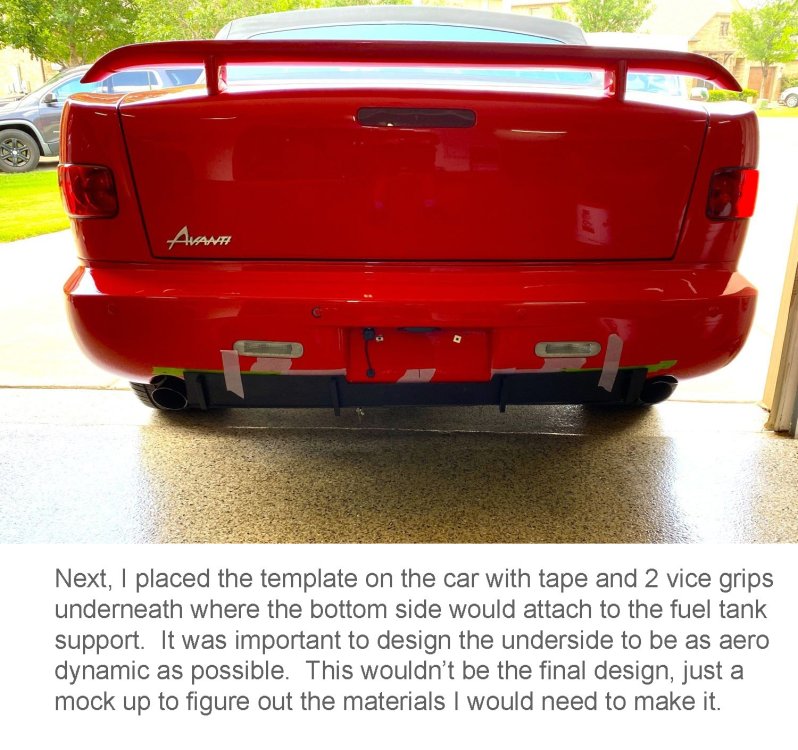

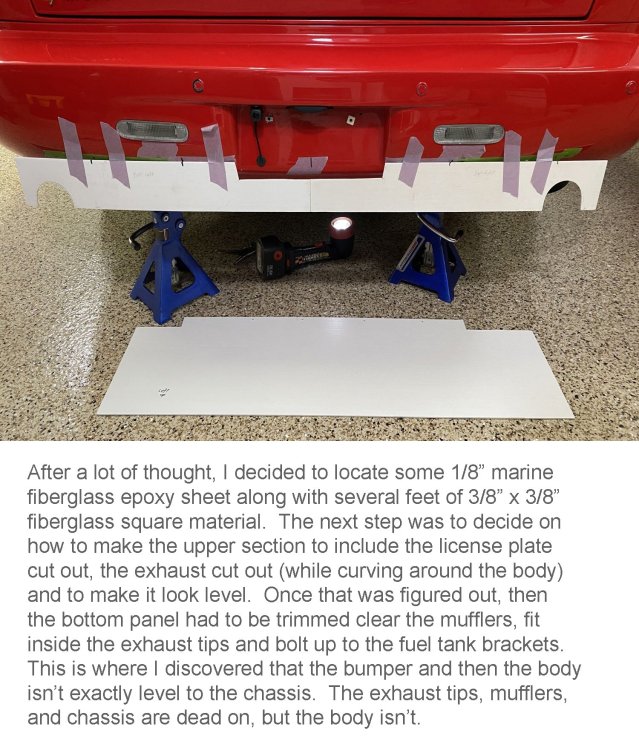

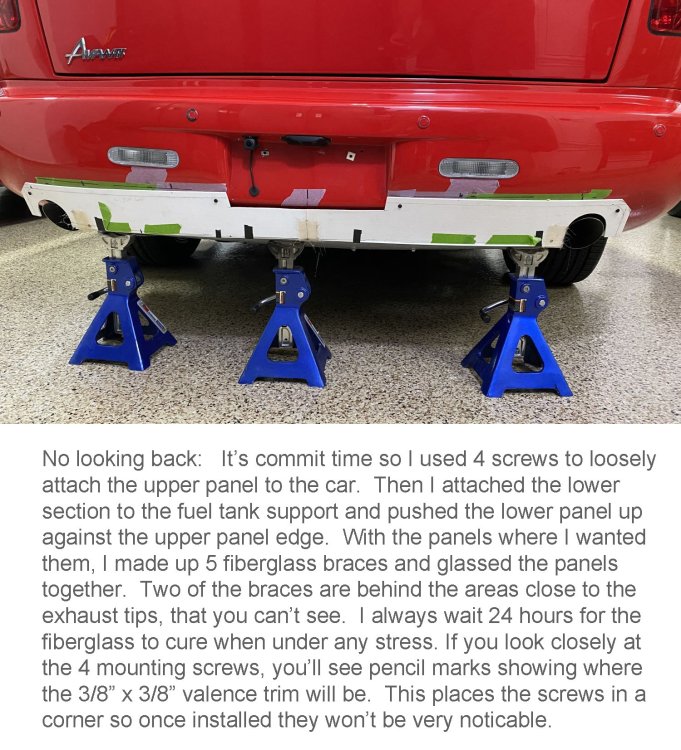

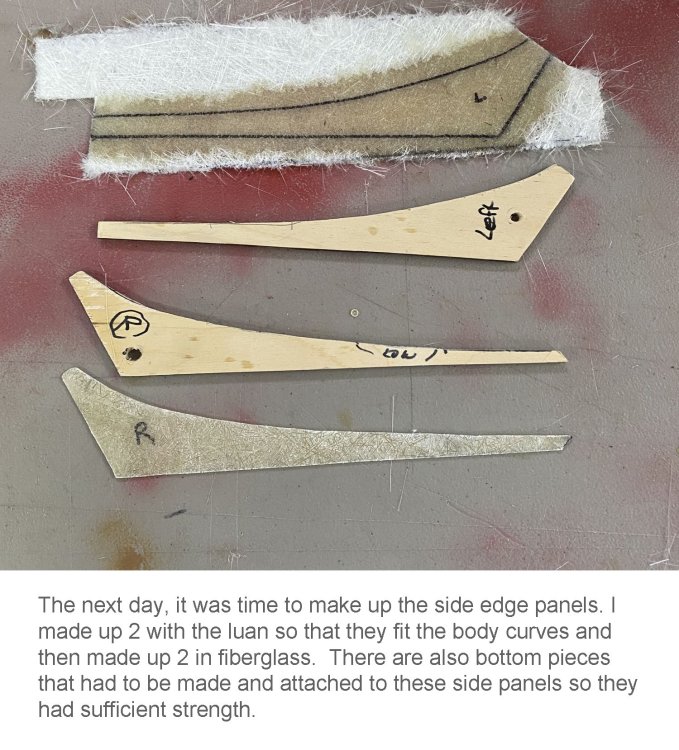

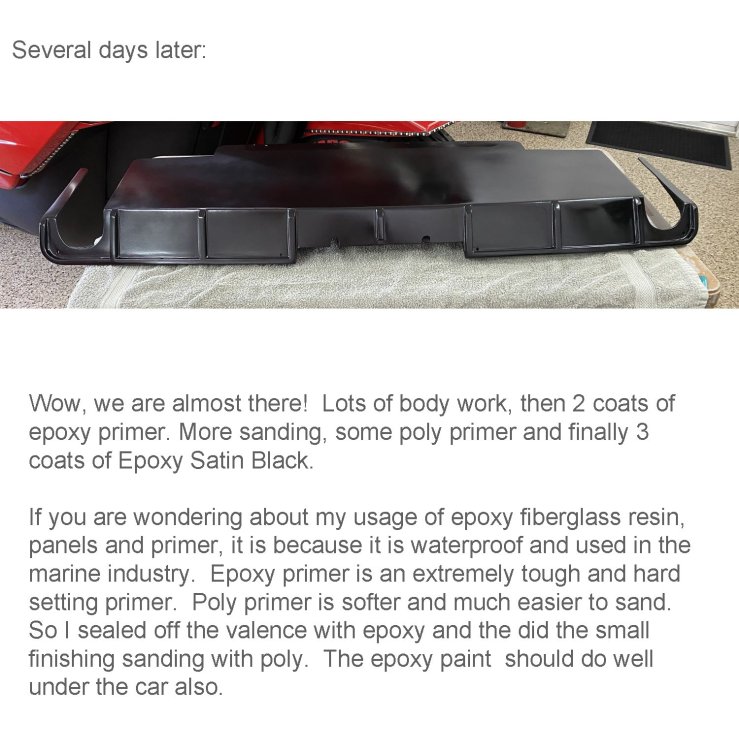

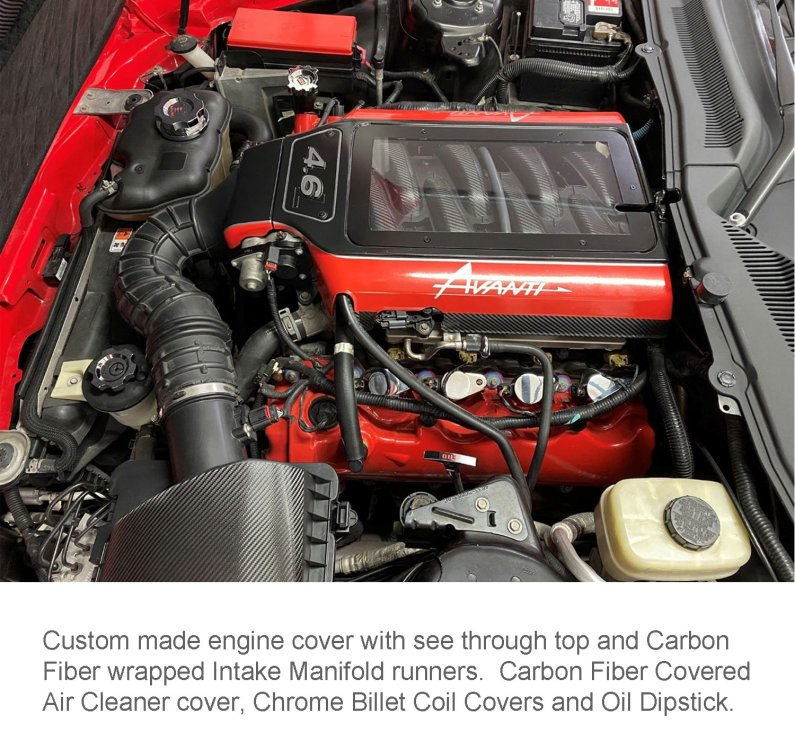

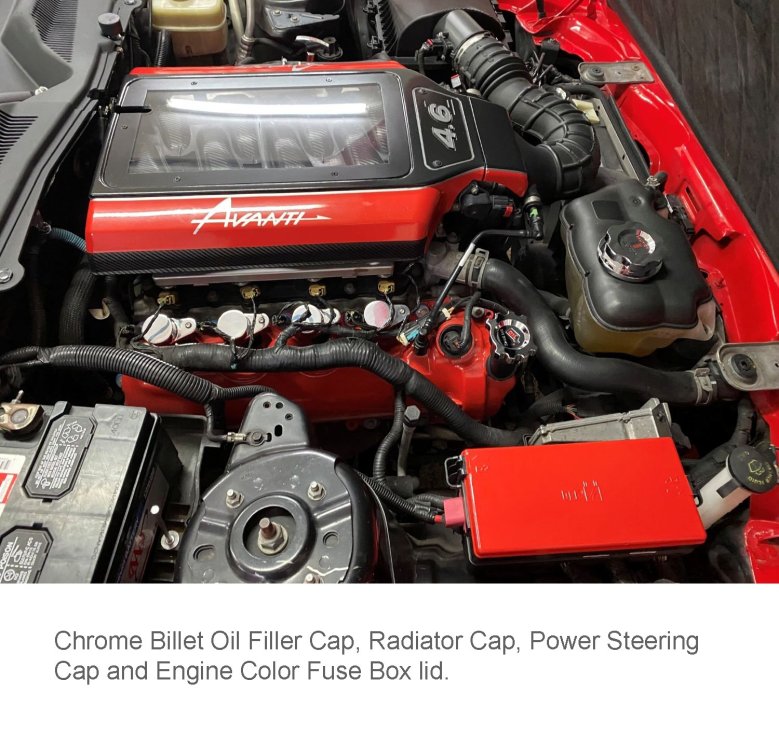

We bought our 2006 Avanti GT Convertible in 2024 from the original owner and it is #11 of approximately 28 cars made in 2006-2007 on the S197 Mustang chassis. I immediately began updating the car to what I consider more modern standards and have posted most of the changes during this year. For our final and most intensive improvement, this post will show you what was done and at the end, I’ll highlight this car’s build. I hope you enjoy it! The modifications to the cars body started with our attending the Mustang Week event in Galveston Texas last April. With hundreds of Mustangs there, I was able to see all of the things that could be done to our car and set out to do each one of them. We got a lot of attention with our “Avanti Mustang” there and next year we are going to blow them away. OK, I’m going to highlight our first 2 body mods and then move into our last, a custom-made lower rear valance.

-

72 Avanti has a line coming from the fuel line drain tee.

ronmanfredi replied to Jim S's topic in 1965-83 Avanti

Some of the fuel pumps had 3 connections on them. The smaller push on fitting was for the return line back to the fuel tank. It is possible that someone installed the incorrect fuel pump that does not have the return fitting on it. If so, you will need to plug it off. -

I'm pretty sure that Dan at Nostalgic Motors has it.

-

That's strange since when I click on mine, I see messages both ways.

-

Built in Nov 82, what is the HP rating of my 1983 Avanti

ronmanfredi replied to forward's topic in 1965-83 Avanti

It is a low compression 305 v8- 155 horse engine. -

You can lower the engine idle to set the timing which takes just a couple of minutes if you prepare everything, then raise it back to their recommended rpm.

-

You should have a VIN # on the drivers side of the dash where it meets the windshield. Take a photo of it and bring it along with the bill of sale to your license department and see what they say. You may have to get a bonded title.

-

Actually Bob's website mentions that both prefixes were used, but the sequence numbers that he has is correct, so it's whatever is on the Avanti VIN plate that counts

-

RQB numbers were not used in 1985. The correct number is AAV-4252 and is shown on Bob Johnstone's website as being owned by Jack White of Charlotte, NC as of 5/2015. You can contact him with a current photo and your information to update his registry: avanti5011@gmail.com

-

3.5 lbs is what my 82 held

-

If you are saying that gasoline is leaking onto the engine where the metal fuel line threads into the carb body, then the only reason for that is the fitting isn't seating correctly when tightening. If so, then double check the flare on the line and carb to be sure they are clean and smooth. If so, then you will use the new filter/gaskets PLUS apply about 3-4 loops of plumbers' tape around the threads of the "Nut" threads to aid in sealing. You want the tape to only be on the threaded area of the nut. Be sure both threaded sections are clean before assembly. A little rubbing alcohol used on the threads before wrapping and installing will help dry off the threads to help the plumbers tape do its job.

-

84 Blaupunkt sacramento radio removal...help needed

ronmanfredi replied to grant mills's topic in Avanti Information

The 7 pin round plug is for speaker amp to connect to the radio. There are 4 positive speaker wires, 1 ground, 12V and switched 12V. The amp takes the 4 speaker signal wires and the single ground input and sends out a pair of wires for each speaker with a + and - for each speaker. (strange set up if you ask me). The radio also had a wire remote option, so I'm guessing that is what the board may be for? -

-

84 Blaupunkt sacramento radio removal...help needed

ronmanfredi replied to grant mills's topic in Avanti Information

The radio puts out a low-level speaker signal to the amp. The amp boosts the signal to the speakers. You need the amp to get any sound. -

I'm pretty sure it's a GM screw in cap. Any auto parts store should be able to supply a cap.

-

Your carb is leaking at the well plugs and the float is iffy if stock. You can get all the parts that you need for your carb model at: https://quadrajetpower.com/ This Texas based company only offer service and parts on Qjets. You can supply them with the carb #, which is on the main body of the carb and they can send you whatever parts you need exactly for your carb. You can also call them for help.

-

Jim, Here are my thoughts on where you are. First, you want to set the electric fan turn on temp at about 180-190, turning it on before the thermostat opens does nothing. It should also come on with the A/C if you have one. Next, I'd remove the thermostat and run the engine without it and see if the problem still occurs. If so, and assuming the water pump is good, then you have a blockage of rust in the engine block or a leaking head gasket or cracked head. There is a tool available that can detect for a blown head gasket/cracked head by detecting exhaust gasses coming out of the radiator cap area when running. (I'd check for that with the thermostat removed so you are fighting the thermostat). If there aren't any exhaust fumes in the water, then a blockage in the engine block is a probability. If this is true, then you can remove the rear most freeze plug on one side of the engine block and get as much of the rust out of that side of the engine. Install a new plug and then do the other side of the engine block.

-

84 Blaupunkt sacramento radio removal...help needed

ronmanfredi replied to grant mills's topic in Avanti Information

The amp on mine was attached with double sided tape. Wire harness plugs into the amp so once I got it loose, it wasn't hard to get out. Then the radio was next. There wasn't a rear bracket on the radio on mine, but there should have been. -

I took the radiator out of my 82 model, had it disassembled, cleaned and put back together. Worked like a champ.

-

84 Blaupunkt sacramento radio removal...help needed

ronmanfredi replied to grant mills's topic in Avanti Information

On my 82 model, I removed the coin/cup holder on top, the knob nuts and pulled the radio out through the top. There was a Blaupunkt amp on top of the radio that had to be removed first. I believe the radio has to be turned to where the side of it comes out first. -

In September of this year, both the Avanti Owners Association International and the Studebaker Drivers Club groups are having a joint meet in Washington County, Pennsylvania. We have created a special limited edition "event" shirt that honors the Avanti Bonneville Salt Flats land speed record with the Studebaker and event logos on the sleeves. T-Shirts, Women's V Necks, long sleeve and hoodies are available in multiple sizes. These colorful shirts would be fun to wear at car shows and club events. You can purchase them here: https://aoai.org/shop/

-

I spent a year working all the bugs out of our 82 model. Electrical, A/C, oil leaks, ring and pinion noise, rebuilt front suspension, etc., etc. But when your finally done, you'll have a nice car and well educated on Avanti...

-

Gound wires in the car are white, so you need to check and see if the ground is good. It is possible that the motor is bad also.

-

One should be +12v (red) and hot when the ign key is on, it goes to the main power terminal of the fan switch. The next one (green) should go straight to the A/C temperature switch on the same panel (the other wire on the temp switch goes to the compressor. The last one (black) goes to the blower motor.