-

Posts

1,111 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by brad

-

Emergency 4 way flashers? Of hand brake light.

-

Curious .. do You shoot for authenticity or modification?

brad replied to aardvark's topic in Avanti Pub

I've built them for authenticity and concourse national non Stude AACA judging for Amelia Island. Also some of them most heavily modified ones using Stude power you will ever see. It depends on customer preferences, and desired shows. -

Rodgers bracket is for a Sanden 508. I made my own bracket, and used a 7176 series. it is serpentine. They do make them in V-belt too.

-

I installed one on the R4 clone I showed at MCACN in 2016. Pretty straight foward installation. I made an aluminum adapter to interface the mounting from the booster and the firewall. I used an adjustable heim joint on the linkage to the pedal. I installed the booster so the accumulator was at the top, and it snuggled nicely into the inner fender cutout for the original brake booster area. If you want to use AN lines, fittings are available from several sources.

-

If you loosen the through bolt that holds the springs, and the two mounting bolts up top, you can shim between the body and the hinge to lower the deck lid. Adding shims between the hinge and the lid itself will raise it. Often when new weatherstrip is installed, it is done incorrectly. It should NOT be glued against the inner rib the the deck lid all the way around. on the sides, and top it should be 1/4" away, only on the bottom is it glued tight to the edge. Also most replacement rubber is too stiff. Mustang fastback wetherseal is much more pliable, and has the same cross section.

-

It depends on the boost levels of the supercharger. anything much higher than stock 4-5 lbs will slip the belts at higher RPMs. Serpentine belts are "grippier".

-

The kicker diaphragm (not the bracket) is the same as some Pontiacs. Not sure what year(s).

-

The turn signal switch itself is located down the column nearer the floor. The cable runs to a bracket on the switch at the switch end, and to the lever mechanism under the steering wheel. You have to pull the wheel. There is no electrical part under the wheel like non-tilt cars except for the horn contact. It is the same as 63-65 GM Saginaw tilt wheels but the column itself is a Stude only part. After 65 they were totally different.

-

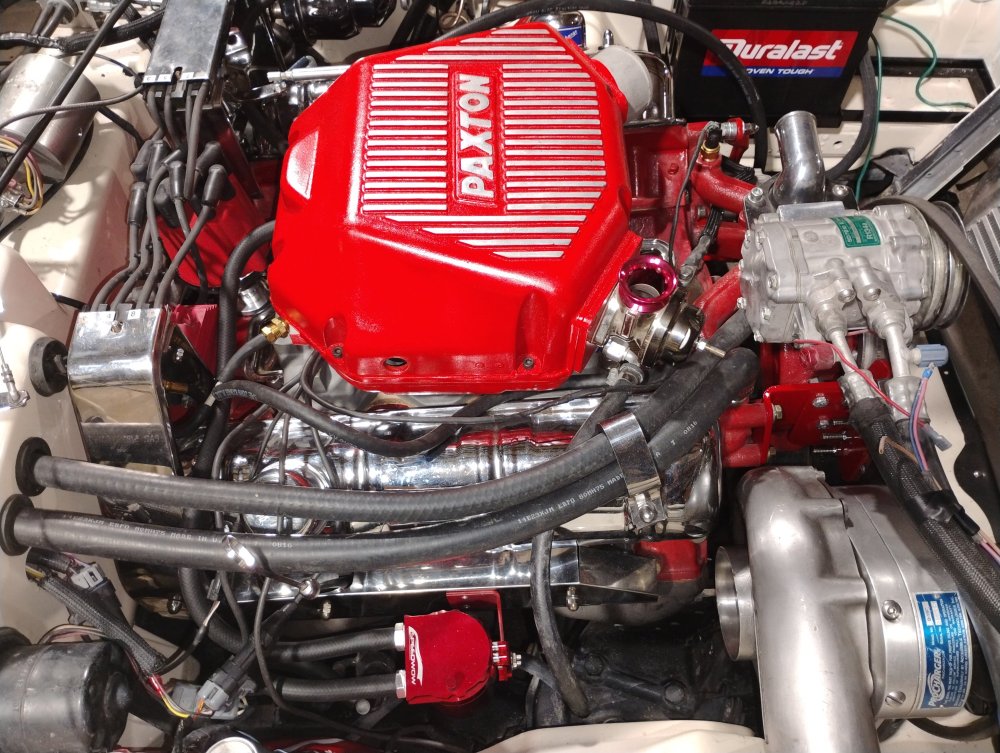

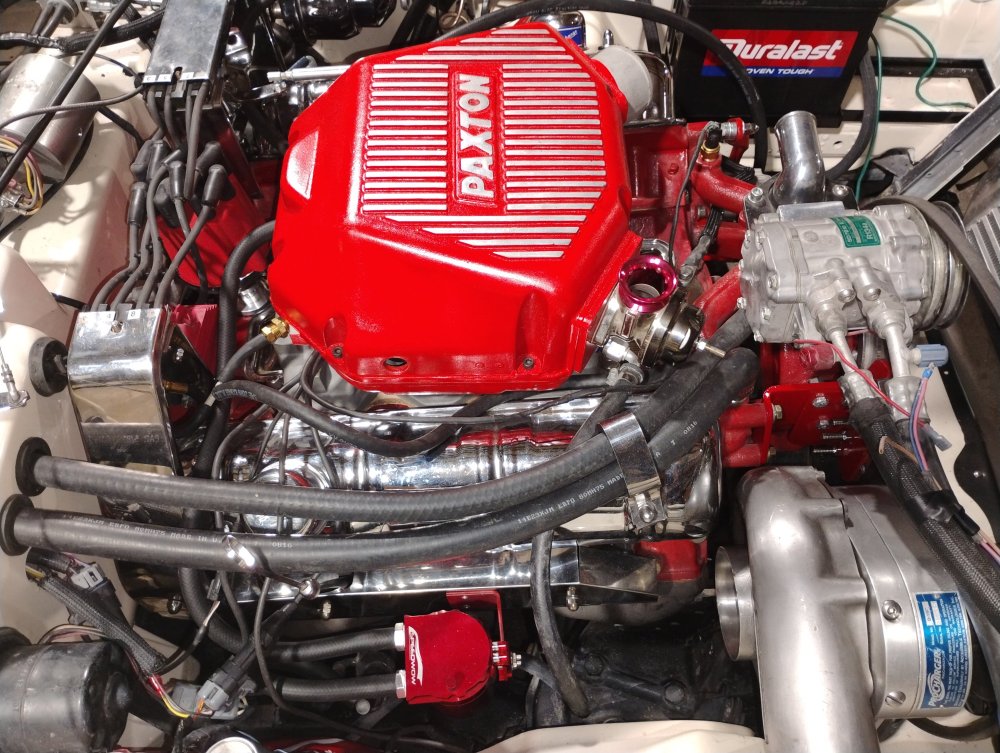

This is one setup I constructed. I used a Chrysler lower pulley and the waterpump pulley is grooved as it has to turn in the same direction. I think I used a Ford belt tensioner. It's been a few years...back in 2016.

-

On the 61 Hawks? They even had dash plaques that touted them as "Gran Turismo" limited edition. James Mason, a British actor posed in the ad.

-

Ed George only has the R5 pistons in his R3 engine. Greg has the original R5 and had a section of the pan rail welded when it had damage. I supplied R3 pistons to Mr. Cone when the originals were long gone. The R5 piston is essentially a regular R3 Forged True but, the crown is angle machined for slightly lower compression. Necessary with two higher output superchargers. The specially stressed blowers would last approximately one run. (7 miles)

-

Every frame off that I do, I replace the rear shackle bushings in the frame while you can access them.

-

Never use 60 year old rubber unless you want to do it again in 6 months!!! Always use fresh new rubber .

-

-

I did one Avanti that someone installed a 62 Lark grille directly in front of the radiator. It bolted to the core support, and was basically flush right in front of the radiator and offered good protection.

-

The motor I took off has 4 wires, the "new" motor has 5. I'm cleaning up the old one and going to reinstall it.

-

I looked at the wiring on Bob Johnstones web site, and it says the red wire is high speed, and the yellow is low speed, and blue is park, white is ground. I only get any movement with power to the black wire. This is with the plug disconnected from the main harness. What is the deal?

-

The two larger pieces are the side console pieces if it did not have air conditioning. They give you both sets. The other two pieces are the lower kick panel that would be paired with vinyl if it was an earlier car (Studebaker) later Avantis were all carpet on the kick panels.

-

The round "can" is a radio noise suppresser condenser, or more commonly called a capacitor. Not any sort of voltage regulator. The other wiring seems correct. The white with red stripe is to the main terminal, the one with the black stripe goes to the smaller terminal, often a spade push on connector if original. Then the plain white wire is ground to the case. The voltage regulator is in front of the master cylinder on the drivers side inner fender.

-

So, there might be two different sizes of fuel pumps used on out cars. I have used this kit before with good results, however on a few ones I tried using this kit on, the top diphragm seal was the wrong size. Then and Now Yesteryear parts also has a good rebuild kit .

-

I have seen some strange stuff on Avantis. I've seen the salt and pepper carpet over the seat hump, with no vinyl riser, and of course the more familiar type that is cut out for the riser that is covered in matching seat vinyl.

-

The Will Carter is right from the horses mouth at the Carter factory that was in St. Louis. Can't get any clearer than that.

-

Compression ratios. The R2 needs more initial advance, and less total advance when the boost comes on.

-

Actually the 64 changes were on an EX prototype car made long before R4892. One of the last ones Gary Johnson is finishing up.

-

There is usually a flat washer gasket sold with the kits, as well as a grommet that goes around the stud on the lid. don't use the grommet, as it is meant for the Ford type with the vented dipstic cap and lid. use the flat washer so the dimples on the top are open under the washer for venting.