All Activity

- Past hour

-

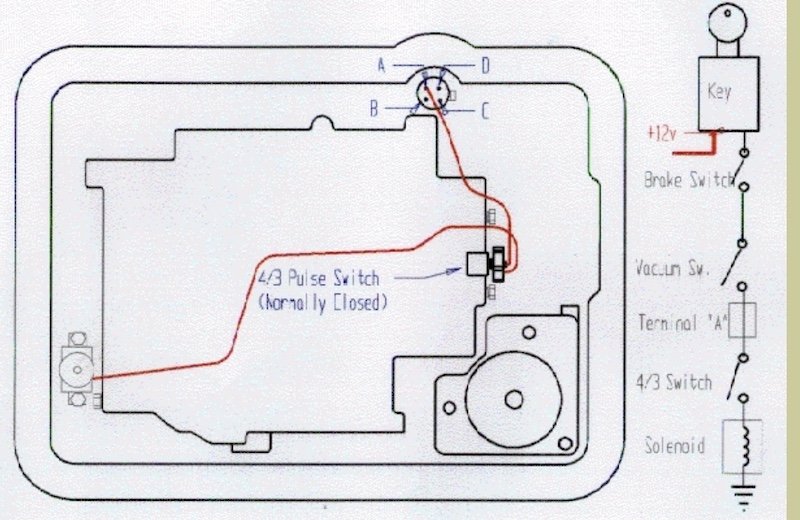

I was out of town for a week, are we still talking about this here? My RQA original came with a 350/300, with a "Powershift" transmission, which was later described as a Ford FMX by a Mechanical associate. The Quadrajet was replaced initially by a Holley Economiser 4 barrel during the 70's gas crisis. It was a bit less performance wise, but the roar of the Quadrajet rear barrels opening was gone and the mileage was up considerably. In the 90's, the car was totally refitted, with the body off the chassis and a Jasper 350/330 and T700R4 were installed. During the cleanup of the install, I found out that using an Edelbrock with a 700R4 was not going to work properly unless you manage the TV cable properly. The TV cable did not attach to the Edelbrock throttle linkage correctly, which threw off the arc geometry required to satisfactorily shift the transmission. The fix for this issue was to buy a kit from an outfit named Bow-Tie OD, which included an oval cam that the cable rested on.... and the cam was moved to various positions initially to emulate the proper GM arc to make the cable act on the TV pressure as required. There was also a new spring for the TV cable and that had to be inserted inside the pan, so the pan had to come off and you get to know you transmission really well. The TV cable was another aftermarket brand and I made the mount where it locks in the setting. Opening up the transmission shows how the lockup was controlled by wiring +12 to the Lockup solenoid using a brake light switch in the 3rd gear oil gallery. Once the governor determines it was time to use 3rd, the gear change was smooth and then then engine dropped another 2-300 rpm or so, when it locked up. When it dropped out of 3rd, the lockup went off. So after the transmission install, I ran a +12 with to the assigned "weatherpack" connector on the side of the transmission and that was it. Once the Bow tie kit was installed, you raise the car on 4 jack stands, have a Transmission pressure gauge fitted to a port, just forward of the shifter lever, start the engine and allow it to warm up, then call the tech line at Bow Tie OD. Once assigned a tech support person, he instructed me to put the trans in 1st and let him know what the TV pressure was. He responds with "tighten" or "loosen" the TV cable at the adjusting point, then it gets a little hazy here as the 1-2 shift on my car happens in the blink of an eye, but I know we went through all 4 gears and once he was satisfied that the TV pressure engaging each gear was satisfactory, he said " it was good to go". It was obvious that you want to "feel" each shift just slightly. I was always worried about the trans overheating, so installed a temperature sender in the oil pan and the gauge went right below the speedometer. The temperature would always hang between 160 and 190 on the road. So after driving it for a number of times, I did not like a few things, the first being the 1-2 shift. Since the car has a 3:54 axle, you'd better not have a cup of coffee in your hand when you depart or you will be wearing it. Another thing is that there is no way to avoid the 1-2 shift, as you cannot start out in 2nd, unless something has been recently developed to do just that. Another issue is that when this car gets to 4th and in OD, the engine is turning about 2200 rpm, but it seems like my engine is lugging or struggling with something and is not smooth. This is what tempted me to get into the transmission pan and see how thing are set up. The trans pan itself is a deep finned aluminum style and it holds about 3 extra quarts. Somehow I think back that this had to do with the temperature thing. With the pan off the filter is easily removed and the wiring inside is obvious and fairly simple. The important part is that there are Oil galleries for 2nd, 3rd and 4th gear. You can put the switch in any one of these and have the lock up 2nd, 3rd and 4th..... or 3rd and 4th or just 4th. I elected to install a SPST switch on the dash and split the +12V supply to the solenoid, to see what the impact would be by driving without the OD. Understand that 4th gear is .66:1 or the like and the power required to force trans fluid through that myriad of blades and orifices of a torque converter to enable OD, can cause the temps to rise pretty quick. I actually watched the temperature needle go from 180~ up past 240 in say 30-40 seconds. When the lockup switch was thrown, the temperature went back down just as quickly. There is a schematic that uses a brake light switch and a vacuum switch inline with the power supply to enable an automatic engage/disengage. There was even an article in an AOAI Quarterly a number of years ago, outlining this procedure. (see pic enclosed)

- Today

-

Make sure you get the power steering ram and control valves rebuilt including new hydrologic lines while the engine is out. I did not and have been dealing with leaks for years.

-

Brake pedal goes almost to the floor before brakes engage

Jim S replied to Jim S's topic in 1965-83 Avanti

That is correct. Your suggestion makes sense as the starter is pulling the majority of power from the battery during cranking. -

Here is a site to check https://www.clocksandgauges.com/home.html

- Yesterday

-

Have one orig. 4 speed trans left for sale. Also, one complete shifter and linkage minus knob.

-

Bill - Any details on your electric fan?? Also what color is your Avanti?

-

Zedman - any part numbers for these engine mounts?

-

Good Morning Y'all.... It has been a little while since I have checked in. Much is going on w/ RQB 3616. I decided to rework my front suspension and rework the engine compartment before I put the engine & transmission back in. I degreased, scrubbed, and pressure washed the engine compartment. and frame. Removed the steering gear, scrubbed, painted, and it is awaiting reinstallation to include a new rag joint. I pulled and rebuilt the power steering solenoid and it is awaiting reinstallation. Received my order of Eastwood rust converter, encapsulaor, & internal frame coating. I have removed the driver side control arms and kingpin. The kingpin got new bearings, a solid, scrubbing, and a paintjob. The control arms and associated parts have also been scrubbed, painted, and are awaiting me to press in the new bushings. I have also started the rust converter / encapsulator effort on the driver side of the frame in the engine compartment..... I have tons of pictures and will them get posted later. I did fail to get the lockup kit installed on the transmission when I got it rebuilt but have picked up a Edelbrock Painless Performance 60109 Torque Converter Lock-Up Kit and will be installing sometime in the near future.... I also picked up the HD sway bar kit and will be replacing the front during all of this. With Fall being here I am pushing to get the suspension and engine compartment work done to include paint before the temps drop to much..... Any recommendation on exhaust manifolds... I was thinking a set of engine hugging ram horns but am open for ideas.... Blessings Y'all

-

Thanks for that idea and the TC lockup info, MFG.

-

Agree with You both, since I'm not generally a purist. And as said, ""Love the Changes!"" As far as my '63' R2, however, ''I am'', and the only anticipated change is Turner Brakes which will show a dual master under the hood. Also Ron... I have seen the valuation go up substantially in Our '01-06' cars just in the last 1 1/2 years I've owned mine. I see the prices meet and exceed the Av1's and mores over the AV2's What really got me started on all Avanti's was when Alice Cooper did a Retro of His Av1... with a Ford Smallblock and suspension upgrades (amongst other changes) by Counts Custom (TV Show). It triggered a long held respect I've had for decades for these cars.

- Last week

-

This 2006 Avanti shows me well thought out, VERY well done IMPROVEMENTS !

-

2006 Avanti Lower Rear Valance

ronmanfredi replied to ronmanfredi's topic in 2001-2007 Avanti models

I don't think there are many purists on the 2000s cars. Even if there are, it doesn't make any difference to me. Valuation of these cars doesn't compare to the 63-64 Studebaker models. I know without a doubt that they will increase the value of the car based on comment made to me at the AOAI - SDC dual meet a couple of weeks ago. My car received a First Place award with 98.33 points out of 100. I also received the Longest Distance Traveled award for 1375 miles driven one way. Since back home, I replaced the windshield since there were tons of small paint chips in it. Final work is a new top due to wear and tear. -

How deep is the clock body? Would it be possible to mount a quartz movement with a long shaft on the back of the body? I have a volt meter in the clock location so I’m just kind of speculating. Mike

-

I have a complete package to convert to standard from automatic, all original parts. Any interest, contact me. Also have complete R1 motor, rear differential, doors w/ manual windows, brake parts, etc.

-

I'm just wondering if there's a small enough quartz clock mechanism available form a hobby supplier that would fit inside the clock body and use the factory clock face...and the AA-battery could be mounted outside of the clock body under the dash. The factory illumination could be retained...just the guts of the clock replaced.

-

I'm in the process of converting to a mechanical switch mounted under the dash that is actuated by the brake pedal arm. I had to cut, bend, and drill two holes in a piece of metal. One hole holds the switch. The other is where it's bolted to the dashboard. I'll add some photographs when I get a chance.

-

If you do install a backup battery, you may need to wire it in such a way that it doesn't try to also power the rest of the electrical system. Otherwise, it might drain quickly if something gets left turned on.

-

Brake pedal goes almost to the floor before brakes engage

Adam DeRosa replied to Jim S's topic in 1965-83 Avanti

So, you're measuring 9V at this wire while the engine is cranking, correct? If so, that may be OK. Verify by checking the Voltage at the battery while the engine is cranking. You'll probably see a similar drop. -

WANTED: Power booster for AVANTI R1, model 1964, R4754

Paul Manders replied to Paul Manders's topic in Avanti Parts

Dear Dwight, I haven't found a booster yet. If you still have one, I'd be happy to buy it from you. I've already purchased many missing parts from Stephen-Allen's and Studebaker International. I prefer to send the booster to Studebaker International, as I can also order other missing parts. Like to hear from you. Regards, Paul -

Brake pedal goes almost to the floor before brakes engage

Jim S replied to Jim S's topic in 1965-83 Avanti

I completed that stage. Now the wire from the starter to the distributor that supplies voltage during cranking is now hooked up. I measured that voltage and it is only 9 volts. How can that be? It's the green wire with black stripe. Is it a resistance wire as well? -

I LOVE the changes as well, but I'm not a ''Purist'' and I welcome most tasteful Mods that are done on a personal automobile (or vehicle) . A "Purist" might take offense or even disgust with the things being done.. How do these things affect overall end $$$ value? Eye of the Beholder, I guess.

-

WANTED: Power booster for AVANTI R1, model 1964, R4754

Dwight FitzSimons replied to Paul Manders's topic in Avanti Parts

Hi, Paul, Did you find a booster? I may have one; not sure at this point. I don't know if there are any rebuilders in Nederland or Europe, but there are in the U.S. Stephen-Allen's in Florida and Studebaker International in Indiana (& probably others) sell them, but require a rebuildable core in hand before they will ship a rebuilt booster. I bought a rebuilt one from S-A and it works well and looks good. If I, or someone else, come up with a core, I assume that either SI or S-A will ship to you. The rest is obvious. I'll let you know if I find one here. --Dwight -

'63 R1 Dashboard Clock: button battery?

Dwight FitzSimons replied to DobbM's topic in 1963-64 Avanti

DobbM, your idea is sound. I suspect that the electro-mechanical clocks in our Studebakers would last longer if always powered up. There are small 12-volt rechargeable or non-rechargeable batteries on the market--just search. --Dwight -

Point taken. I did another search and this was discussed over here: https://forum.studebakerdriversclub.com/forum/your-studebaker-forum/tech-talk/80418-clock-ideas-replace-or-convert Sounds like a good winter project.

-

It will take more than a button battery to run a mechanical clock designed for 12v. Average button 1.5v and even if you put 8 in series to get 12v it wouldnt have the amp/hr capacity to run very long.