All Activity

- Today

-

Let’s just say… More ‘natural’ than a 426 Chrysler Hemi !!!!!

-

I’m ask the administrator about this BTW …AG-R3.., your profile indicates you own an early ‘A’ series Avanti ll. That wouldn’t have a lockup converter… Or has it been retrofitted with a later ‘Turbo’ transmission?

-

That’s strange!…. I never requested to not receive messages

-

....... your PM capability has been rescinded.... You will get a response stating you "cannot receive messages"

-

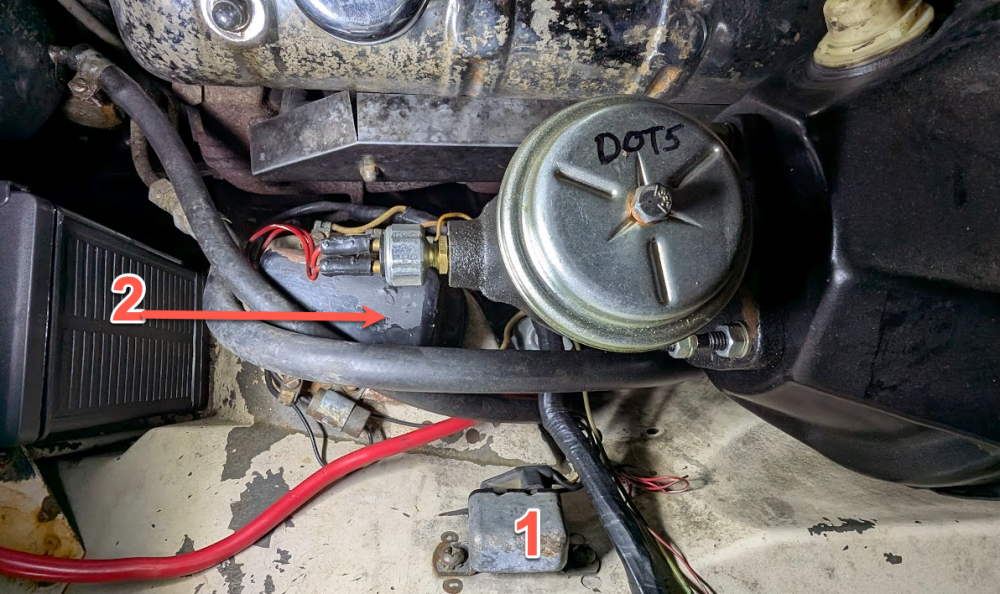

Yes … black ‘box’ marked 2

-

-

Still waiting for my shop manual to arrive. Thank you for any advice. It takes the brake pedal to be pushed about 95% of full range to activate the brake lights. Aside from slamming on the brakes for an unexpected obstacle, I don't think I ever really have the pedal go that far. It appears to be a hydraulic switch on the master cylinder, so not adjustable. Correct? The fluid is full, and since a trusted mechanic replaced all the brake lines with stainless, I'm sure that they were bleed properly. Also, the brake booster was rebuilt, and a new master cylinder installed. The brakes themselves work fine, and no squishiness, etc. A). Should I try and bleed the lines first to help diagnose (or if I need to replace the switch, I'll have to bleed them again). B). Do the switches fail? Or should I be looking elsewhere for my perceived issue? C). If they do fail, where might I start hunting for a new one?

-

Yes, those kits can be pricey, not to mention the labor costs of a qualified transmission technician to install it. A manual switch is a practical, common sense way to handle this converter lockup issue… I’ve been using one for about 15 years in my ‘everyday driver’ ‘83 Avanti. However, what you describe is a bit over complicated I think… I can describe to you a much simpler way to handle this… If your interested, PM me on this forum.

-

Thank you 63r2 for the information and the reminder. I should have remembered to look at my parts catalog to see the diagram. I still would not have known the background that you provided. I saw the inlets you described but never questioned what they were for. Now I know. What did you replace your hoses with? OEM (if available) or aftermarket? The first foot or so of the hoses from the top on each side seems OK, so I thought I might try to get a larger hose to slide over it and run it to the shifter area. I left about a 1/2" of the old hoses at the shifter so I can slip the new hoses on. The hoses are 1-1/2". Hopefully this will save some work and achieve what Studebaker tried to do.

- Yesterday

-

Point I was making is it being ''Natural" is not a way to describe it..Natural is back to a Chev SB. And I have to think the installation would fit but a lot of small stuff would need addressed.

-

Well, can you think of any engine that would be easier to install into an Avanti ll chassis than a Studebaker V8? ( With the hypothetical assumption that an owner wanted to part company with the factory installed Chevrolet engine)

-

I thought that site was dead?

-

I question the ''Natural''. It's more like a confusion.

-

Nope… not me…. I just wondered if any Avanti owner had ever attempted it…. after all, it would be somewhat a ‘natural’!

-

Good, because that was a real problem that I actually got stuck with. So why the question? Are You considering a 3rd swap?

-

Brake pedal goes almost to the floor before brakes engage

Zedman replied to Jim S's topic in 1965-83 Avanti

Jim- I dropped the ball on the subject of Proportioning/Combo Valves, and forgot to mention what ALSO needs to be done.... If you have tried to bleed your brakes without the 'Special Tool' and the Shuttle Valve has indeed moved over- then you must RESET the valve manually (i.e. re-centre the shuttle). There should be a little 'pin' on one end of your valve, often covered by a rubber cover (just visible on the brass valve in the picture I posted). This pin may be sticking out somewhat, indicating the valve has moved over. You will need to push this back in otherwise the 'Tool' will not impinge on the groove in the middle of the shuttle. However, because your front brakes are operating, the shuttle valve will have moved inward. To help re center it, crack a bleeder on one of your Disc Calipers and give the Brake pedal a push. This ought to simulate a front brake "failure" and the shuttle valve ought to move the other way. One way or another, just ensure the Shuttle is centered before screwing the Bleeder Tool all the way in. Sorry for long explanations, but as an ex high school teacher, I know that you can't afford to throw doubt. - Last week

-

I think the soft came issue was rectified in 1988 (when GM reworked the small block Chevys… also improving the rear seal and one piece oil pan gasket… My 305 engine was purchased around 1994… but sat under a workbench for years after being pulled out of the street rod.

-

I had the piston (York?) compressor replaced with the Sanden compressor while the car was getting a paint and interior makeover. The guy welded an adapter plate (currently available through Vintage Air, I believe) to the original mount bracket allowing mounting of the rotary compressor. Looked like crap, crankshaft and compressor axes did not quite line up, I hated it. Vintage Air has mount brackets for various makes and models. My compressor is mounted on the passenger's side with the power steering pump on the left. My A/C hoses come out of the dash on the passenger side, hence the compressor on that side. I don't know about your 350, basically the same block as the 327, but the 327 had either a long or a short water pump and, hence, different pulley arrangements and accessory mount brackets; I don't know if this applies to your setup. (I consulted my friend, Mr. Youtube, to figure mine out.) Vintage Air has brackets for both. For my 327 with the short pump, Vintage Air's p/n is 15126-SCA. If nothing else, this p/n can get you to the listing of the GM brackets. As I recall, their website was a bit tricky to navigate. Regarding Vintage Air, their jigs for patterns are right on the money and they use very good metal and the brackets have very good welds. They provide the bolts and spacers for whichever application you have, (e.g., Ram Horn Manifold, Drop Type Manifold, ...) and the tolerances are very tight. You get to paint them as you choose, no paint from the factory. They illustrate which bolts and spacers go where; however, their other written instructions are vague. They provide written instructions with the kits but you can also view these with the kit itself and print these out. If you go this route, I'd recommend print them out and perusing them before purchase as you can familiarize yourself ahead of time. It is a bit of a puzzle and you can figure it out; just don't imagine that you'll figure it out in 5 minutes. They could easily include more detailed pictures; this is my only complaint. Overall, very good value for the money and I'm very happy with the results. Good luck! Keep us posted.

-

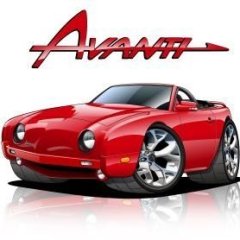

The hoses you describe are ducting to cool the shifter/console area. As you describe they terminate at the shifter but they start high behind the dash underneath the grill in front of the windscreen. If you look under the dash in that area you should see two round fittings (one either side of the trans hump) that you attach the other end of the ducting too. If you look through the air vent grills in front of the windscreen (from the outside of the car) you can see where they terminate. The ducting was a later idea from Studebaker to try and lower cabin temperatures. The idea is that fresh air is drawn from that outside vent area and blown onto the shifter area to lower Temps. I only replaced my ducting about a month ago as it had rotted out as well. From memory the ducting was around 2 inches in diameter. Pb

-

I have a '67 Avanti. Trying to figure out the routing of the ductwork hoses. Most puzzling are the two hoses that run along the inside of the consul (one on each side) and terminate into the space where the automatic shifter is located (probably so mice can have an easy access). I'm not sure where the other ends end up. The hoses have deteriorated and the one I touched broke into segments when I tried to move it. I was assuming these were ac hoses until just now as I was typing this, but maybe there weren't any hoses for the ac. The ac may just blow out the two front vents on the consul. But why all the hoses? Any ideas? Is there any diagram or drawings of how this is laid out? I have a R1 and a R2 but neither have a/c so no help there!

-

How many Avantis are still in existence?

Mark63Avanti replied to Ronny Daytona's topic in Avanti Trivia

I looked back through my browser history and I was trying to update "TheAvanti.com" -

Only issues I ever had was soft came on a 305. But if You've gone that far.. not a concern.

-

I’ve heard Avanti Motors, during that period, converted some of their ‘electric fan’ cars back to a standard Chevy 5 blade clutch fan & shroud… due to insufficient cooling with the factory electric fans. My ‘85 Avanti has the electric fans… and frankly I’m not a ‘FAN’ !!!!

-

Here is the mockup with the existing inline filler, replacement is on order. The radiator to filler hose is a Dayco 81311 - 11.25" long, the filler to thermostat housing is a Dayco 81321 - 13.25" with an All Star Performance (Amazon) ALL30240 1.75 to 1.5 reducer. The Dayco reducer is 76950. Gates also sells a reducer 26391. The hoses are pretty stiff, but can be persuaded into shape. The inline filler connection was zip tied to the fan shroud to keep the hoses "shaped." This was how it was configured when I get the car. This adequately clears the A/C hoses, Compressor belt and aligns with the thermo housing. Note that the car originally came with an electric fan and the original owner converted to a shroud/flex fan assembly. I would like to go back to an electric fan - flex fans scare me.