-

Posts

1,076 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by brad

-

-

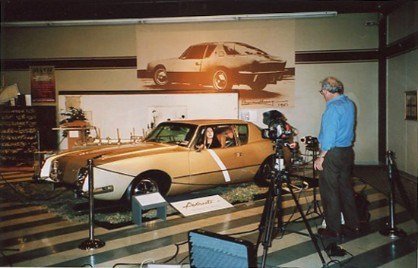

it was Steve James AVX convertible.

-

I redid a door handle on an AVX that was Harlequin gold to red. The paint was 200 something for 2 ounces. The cost for a gallon would be over $5000. The paint supply house still tells people I got the most expensive paint he ever mixed for anyone.

I cost out a beautiful red pearl paint I would love to do an Avanti in someday, but, it is over $2000 a gallon

.

-

-

Less rotational mass (quicker revving), and less HP drag to run.

-

Nope Every engine with a fan can be vicious. Watch your fingers!

Perhaps he means viscous???

-

I would say it would help slip the brake booster pedal rod through the firewall boot.

-

It's three. the standard 5 blade fan, the hd 7 blade fan, and the cut down 14" fan as on the R3 and 4

-

-

-

Not quite true. ALL bodies were MADE at MFG. What you are referring to is ASSEMBLY of pre-esxisting parts

-

-

I always take words like "most" and "experts" with a grain of salt.

-

It depends on the serial #. Early versions were vinyl, and carpet glued to a carboard inset about 1/2 width of the panel. The carpet, and vinyl were separated by a stainless trim piece screwed to the panel after installation. Later versions were all carpet, and also had a plastic grille screwed over the vent opening.

-

The 1/4 window seals are currently in the process. Also the "A" pillar seals with the correct molded ends. Also better bumper end rubbers.

-

Then what are the white with red texture grip end filters? It would be good to provide pictures, and documentation.

-

Been inspected.

-

The horn button

-

Just because someone says they have the original molds, does NOT mean they actually utilize them. It (as always) takes someone to step up and make the parts for customers.

-

-

The recommendation to pack the area with grease (for lubrication)is absolutely not true. What they ARE recommending is to pack the push rod hole with grease so the rod stays in place while installing the pump. They do not have the arm riding on the drive eccentric like some cars, but in actuality have a drive push rod. The only reason it MIGHT have a oiling problem is if non stock gaskets were used between the first mounting plate, and the block. There should be no gasket overlap between the pump body opening, where the pump actually bolts to the adapter plate. I have worked on May SBC engines, and NEVER saw ANY oiling problems ate the fuel pump. They simply do not exist.

-

five...or in this case 3!?

-

The water pump. Nothing will flow until the thrermostat is open. Changing to a bypass thermostat will make a small change. Changing to a large bypass opening in the water pump will make the largest change.

-

I thought they went from the 400 cu. in. to the 305.

-

Elaborate please.

rear quarter window seals

in Avanti Pub

Posted

No, they will be out around the middle of April. I have tested the prototypes, and they are perfect.