-

Posts

382 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Leo B

-

-

You really have experience. Everything was correct except the thick reinforcement plates. They were on the wrong side. Now OK. You are important helpers🙏👍😃

-

Hey. I bought new rear brake drums and have the old tapered axles. Now the drums touch the backplates on both sides. Old drums didnt do that.

Do you have any experience with this? Are the new drums / hubs dimensioned only for new axles?I got answer from Russ / Studebaker Parts. Should be same for old or new axel. Maybe mine old ones are just too worn beacuse I have opened drums many times.

-

I have T-tag and TwinTrack tag on my Dana44 but missing Gear Ration Tag. Havent found 43-13 (3.31) from ebay so far.

I think that tag should also be in 1963. -

Hi, If somebody is interested how Dana Spicer model 60 and 70 Twin Track / Limited Slip / Powr-Lok works, please check this SERVICE MANUAL BULLETIN 5315-3.

https://media.spicerparts.com/cfs/files/media/ahd5WcQ3TvJismpvQ/5315-3.pdf?store=original

-

Here is the answer. So my first idea and photos where correct or at least good if you dont want to have very loud sound and work like no resistance at all.

-

This is from Nostalgic Motor Cars. No marks on muffler. Sold like this "replaces glass pack P#1557754." I asked how to install this. Dan B. told that it is possible to use both way. I understand this that glass pack has more resistance when "gills" are open towards engine/flow.

-

-

After looking webpages...

The gearbox is same as Ford Mustang T10-B-1 http://www.mustangtek.com/transmission/T10B-1.htmlTail is T10-7B which is from GM.

Did Studebaker use this combo in Avanti 1963? -

-

Hi,

Please advice. I have Borg Warner and marks T10 B-1 and T10-7B and on the cover 8-9-62.

What is the type of this 4-speed T10 and where to get good kit and parts? I like to rebuilt this Gearbox.

1, 2, 3 are loud and I have not open gearbox yet. If you have any tips on what to check, I'd be happy to receive them. -

As you can see, no one knows for sure. I hope you get this sorted out. Are there still people here who worked at the factory back then? Even pictures do not always tell the truth if their place and time cannot be proven. If I understood correctly... if Studebaker installed one R4 to Avanti, it was done as a test or made-to-order build. I hope you can figure out this historical matter.

-

In SDC forum its said that R4 was only made by Studebaker to 64 Daytona hardtop, four more R4 cars.... Daytona convertibles/GT Hawks for testing/speed runs at Bonneville. No Avanti.

Read more: https://forum.studebakerdriversclub.com/forum/your-studebaker-forum/general-studebaker-specific-discussion/97470-did-studebaker-build-any-r4-enginesYou find also R4 emblem and factory photo engine in Daytona R4 (first page).

At termination of production R4 engine could be bought from Paxton Products Division.

https://www.studebaker-info.org/AVDB1/R2000/63R2328/R2328.htmlHope this helps.

-

Thank you Nelson. Good point. I checked part number and its #1557249 which seems to be Standard in Parts Catalog. I will fix springs.

-

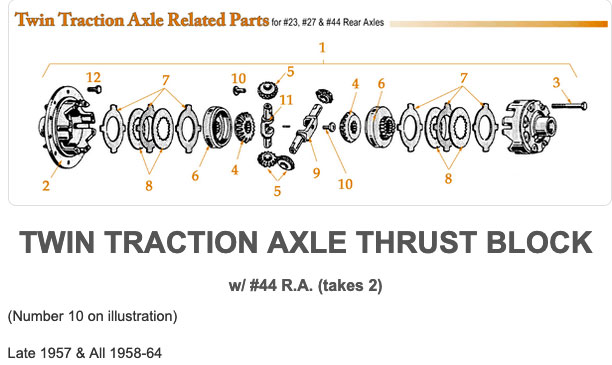

I think I solved the installation of the axle thrust blocks.

The small pin in the previous parts picture between the thrust blocks is a Spring Roller Pin. After cleaning the blocks carefully, I noticed a broken pin inside blocks. Size is 3,17mm x 25,0 mm. (01/8") I understand that the purpose is to hold the thrust block pieces together during installation. The blocks work separately, so the spring roller pin will not stay intact for a long time. And that's probably not the intention. Pin pieces will not come off inside differential because pin breaks in between and pin parts stays inside thrust blocks like it was in my case.

-

Yes MFG. Maybe Street Drag Races, lot of Burnouts?

Twin Track was worn out in ten years and the brake pedal was also very loose laterally (Brake and gas pedal used with one foot.)🤔 -

5 minutes ago, Gunslinger said:

Torque.

👍 Thank you.😊

-

Hi,

Please check. I think the ends of the rear springs are bent. At least one inch and the other is even more. These are returnable.

Interesting thing is that its written in Workshop Manual: Align bushing with holes of hanger and intall the bolt but not tighten. Use the lower hole on the left and upper hole on the right side.

Is there other reason than weight?🤔 -

Now comes the interesting thing.... 🤔

Inside the twin track are two axel thrust blocks (10) that are thru pinion shafts (9&11). When you remove the axles before whole differential, they fall into the axle tube and you won't even notice it. Getting them back in place so that the whole differential is in place is very difficult.Thrust blocks have small hole. In the parts picture there is a little pin between them. That pin doesn't have a part number and I don't have the pin. Of course I can do that.

Is the small pin meant to hold the thrust blocks (10) together? If anyone knows, please tell.

In any case, my intention is to study their function and mission. -

Hi, I found the answer:

Plates:

Late 1957, (.096-101), 1958-59 All Models & Possibly 1960-64 w/ #44 R.A., (1957-59 takes 6, 1960 & Later takes 4). I have 4 plates and 4 discs, which is correct.

Hope that new axle thrust block, plates, discs and side gear rings will make this like a new. Lets see. -

I opened Twin Track for the first time, so it's a new thing for me. It didnt work and I found something interesting. Thrust block (red circle) was missing and all plates where flat. The Parts Catalogue shows 5 plates per side. Work Shop Manual shows 4 per side.

Strange is that in Work Shop Manual is written also 5. In work shop manual Fig.15 Shows 4. In text is written three plates and two dished discs which makes 5.

Im confused. Which is correct in 1963 Dana 44 TT. 4 or 5 plates (plates and discs) per side?

I have 4 as you see.

-

2 minutes ago, Dunkin said:

Leo, thank you I think I am going to try the Epoxy Metal first.

Hi Dunkin. Remember to tell results. This will help all of us to solve interesting problems.😊

-

17 hours ago, Dunkin said:

I took it there today, and they didn't bring the solder solution up. I have thought of what you suggested also, I might try doing it myself, also there are some epoxy metal compounds out there, that are supposed to work. I will look at turning it over also. Thank you both.

Epoxy metal compounds are ok. Lots of choices at retail like Locktite etc. There is not a lot of pressure. You only need to make sure that the compound can withstand the heat of the water. This is a quite easy job. Clean well and make a flat layer. This way you don't do anything irreversible.

-

I would first clean it very well and then would fill all holes with Metal Repair / Rebuilding Compound. The best brand which you can find is Belzona.

Only professional companies have this. I have used it. Of course you can find other brands from retail. -

Lowering Kit for Avanti

in 1963-64 Avanti

Posted

Hi, Im trying to find Rear Lowering Kit (1") for Avanti -63 Dana 44. All I find are 3" wide for newer ones which are too wide. Correct Should be circa 2.5". Where to get correct?