64studeavanti

-

Posts

588 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by 64studeavanti

-

-

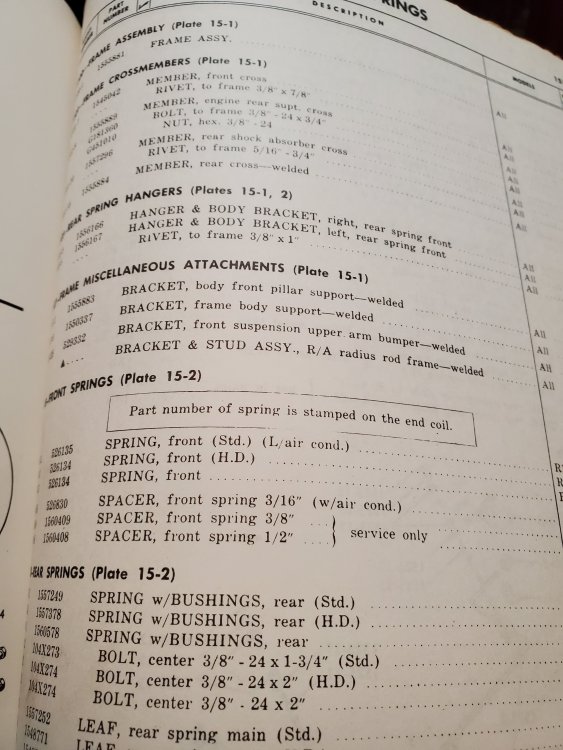

1560480 is not listed in the Studebaker Avanti parts manual! The parts manual clearly states that 3/8" (part number 1560409) and 1/2" (part number 1560408) are service only. That indicates that they were not factory installed.

FWIW, later Avantis used an aluminum spacer approximately 1/2" thick. I do not know when they changed, but my 78 is so equipped.

-

Just measured one of my spare spacers. It is approx 3/16".

-

-

I believe they are 3/8" as they are not 1/2 or larger. That would be for factory. There were other sizes available.

-

AFAIK, the street address is current. I recently ordered and received some serial number plate decals.

-

-

The air intake on the cowl drains down the area behind the kick panels to the hog troughs. You need to make sure the area where the floor and the fiberglass behind the kick panel meets is sealed and the cavities are clear of debris. Also make sure your hog trough drains are clear.

There are a few other potential leaks. Stan Gundry's book "What the Shop Manual Won't Tell You" has a section on keeping the interior dry.

-

I thought you had a document from TRW/Ross???

-

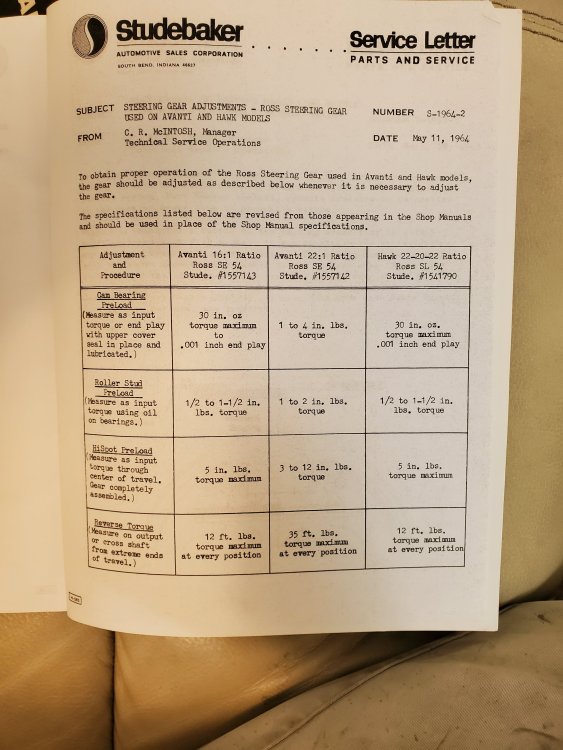

Here is a copy of a service letter dated May 11, 1964. It shows the 16:1 and 22:1 steering ratios for the Ross SE 54 as used in the Avanti as well as the SL 54 used in the GT. FWIW, if you do the math, 16:1 comes out to about 3.5 turns lock to lock and 22:1 is about 5 turns. This corresponds to the data published in the shop manual. If there is any documentation that states differently, I would like to see it!

-

J series plugs have 3/8" reach. H series plugs are 7/16". The thread on both is 1.25mm which is roughly 20 tpi for us non-metric folks. The difference in reach is 1/16". That is approx 1.25 threads. The 1.25 thread difference is likely not significant.

Since your motor was not a combination engineered by Studebaker, I would start with Autolite 437 or equivalent and check the plugs after a couple thousand miles to determine if you need to go hotter or colder.

-

I don't have any 582 heads for comparison, however the studebaker part number is the same for the 582 casting for trucks as well as R2. It is logical that the heads are the same as well. The heat range is likely more significant than the reach. Studebaker originally recommended J9Y for Avanti and JT engines. A hotter plug J12Y was specified in a service letter with J10Y being one step cold for sustained high speed driving. I believe they also specified a hotter plug H18Y instead of H14Y for non Avanti/JT engines.

I believe the H series plugs have a 7/16" reach. I do not believe H14Y are available. However many have been successfully using Autolite 437.

-

Here is a copy from the shop manual. Original pumps have 6 screws attaching the pieces. Modified mopar pumps have more, I believe 8 screws. This is the version with the return line off the fitting at the pump and a metal can filter. Newer versions used a glass filter with the return line originating there.

-

Perhaps terminology issues. I realize that the J and H plugs have different reach. There are some noted Studebaker folks who insist that the Avanti heads are machined differently for the shorter plug. I am obviously not one of them. All 570 heads have the same part number. If the machining was different, there would be a separate part number so they could be ordered correctly. Additionally, it has been my observation that all the heads I have, regardless of casting number, are machined the same for spark plugs.

-

Are you absolutely sure about the depth of the spark plug sockets being different? I have several sets of 570 heads from various Avanti engines as well as older 294, 555 etc heads. As near as I can tell, the spark plug sockets are the same. Additionally, the part number for Avanti 570 heads is the same as for non-Avanti 570 heads. How could you order, or the parts guy get you the correct head, using the same part number?

-

I purchased a set from Phantom about 15 years ago when they were still delivering the goods. I also purchased a set in 2015 from Auto Custom Leathers that I have not installed yet. They look to be pretty good. Studebaker International is listing sets as well.

-

The staples are fairly shallow. I used a pneumatic stapler, but I imagine an electric one would work as well.

-

P205/75R15 while still available are getting hard to find. I am sure someone can chime in with a suitable 70 series such as P225/70R15.

They are pricey with long lead times, but Coker has a 670R15 which is supposed to be a direct replacement. It may even fit in the spare wheel well. I ordered some early February and have been informed that the earliest I will get them is April 30th.

-

Rear seat is pretty straight forward. There are steel rods between the foam sections that the covers attach to with hog rings. Then, you attach around the sides with more hog rings. Front seats are a little more difficult. There are also rods between the foam sections. Tack strips are attached to the seat bottom and seat back to staple to. Hidem welt is used to "hide" the staples. Additionally, the front seat covers are glued to the bottom of the fiberglass shell. I will try to post some pictures tomorrow of how the seats are put together.

If you have the later "thick" seats, the tack strip is attached to the reinforcement that runs along the top and sides of the seat back.

Hopefully, your foam is in good condition.

-

My experience has been to use a hydraulic press. They are really in there good.

-

I believe it depends when it was made. Most 63 have steel can and most 64 have glass bowl. There are good descriptions of both in the authenticity manual.

-

Just checked my 64 Avanti with power steering. Lock to lock is just over 3.5 turns. So, that spec is correct. I do not have a manual box to compare to.

-

FWIW, if the turn to turn is incorrect, then the ratios of 16:1 for power steering and 22:1 for manual must be incorrect as well since the math works for the published values of turn to turn and ratios.

P.S. I do know that the ratios are slightly variable depending on how close you are to the high spot.

-

Just for posterity sake, will you post the bulletin? I have been collecting most pubs relating to Avanti and I do not have that one.

-

Avanti Spacers!

in Avanti Trivia

Posted

So, you believe SI over the parts manual. I hardly call that accurate documentation. You have documentation that states that Studebaker installed SIs part at the factory?