Rick Allen

-

Posts

151 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Rick Allen

-

-

Saw this on a facebook Avanti swap page, saying this rebuild kit for a Ford is the same as the Avanti pump but high quality and less expensive than the other vendors; could it be?,,,

Carter High Performance X Fuel Pump Rebuild Kit - Dead Nuts On

-

On the 289 R2 can the oil pan be removed to access the bottom end of the engine with the engine still in the car? And is it just a matter of removing the oil pan bolts or does the engine have to be lifted also to remove the pan?

-

6 hours ago, A0136 said:

I don’t have a NOS rotor to measure but I just miked a new reproduction rotor and it was .371

If the reproduction rotors are manufactured to the original factory specifications, then that is good to know.

My original rotors measure 3.65 so they're in good enough shape to resurface, they only need to be cleaned up,,,

-

The manual lists the factory thermostat at 170 degrees but seems one of that temperature range is hard to find so what is the best choice for an R2 engine, a 160 or a 180?

I should add that the engine is newly rebuild, so I would imagine more friction initially so more heat?

-

20 hours ago, mrfeez said:

On my 63 Avanti (289) I have a opening about 1 inch in diameter that appears to be threaded, it is located about 3 inches in back of the Oil drain plug, can anyone tell me what

this is for ? Thank You ( I'm working outside under the car, no garage) Old Tom

Is this on the oil pan itself? A picture would help a lot,,,

-

I have a friend that has a 3.31 TT from a '63 Hawk, is that the same as the Avanti rear?,,,

-

Couldn't find the minimum thickness of the factory disc brake rotor in any specifications section but found a small paragraph in the brake section saying the minimum thickness is .330", is that correct?

-

My steering wheel has developed some play at both ends where the two metals spokes meet the wheel, and I see some small stress cracks in plastic where the metal spokes

attach.

attach.

I need to repair this before it gets worse, luckily the steering wheel itself has no other cracks or breaks, appreciate any suggestions on how to make this repair,,,

-

1 hour ago, A0136 said:

Thanks, that's good to know that they fit and are working well so far,,,

-

Nice ’63 R2 up for auction on bring-a-trailer, lots of pictures (and videos) and documentation but I was under the impression all R2 had 160 MPH speedometers, this one shows a 140 speedo; did any early R2 come from factory with a 140 mph gauge?,,,

-

I'm thinking of doing a body off restoration myself and I'm curious how many bolts hold the body to the frame?,,,

-

7 minutes ago, 64studeavanti said:

526956 is the casting number for all rods odd or even. There should be a stamped cylinder number, 1, 2, 3 etc on the rod and cap where they fasten together. As long as you install them in the correct cylinders and orientation, you should be good.

Yes, there is the 1-8 cylinder numbers on the rods; putting only casting number on parts is very confusing for someone like me, thanks for the clarification.

So any rod with that same casting # is correct for an R1/R2 engine?

What do the other numbers mean, if anything, date codes, foundry, etc. ?

-

In the process of rebuilding my ’64 R2, have new pistons and am ready to put the connecting rods on.

The book calls for connecting rod #s 527114 for odd number cylinders and 527114 for even, my connecting rods numbers are 526956 for all 8 pistons and I’ wondering why the number is different than what the book calls for, I’m sure the engine is original and never apart!

Any feedback is appreciated!,,,

-

In the process of rebuilding my R2 engine, I ordered all the parts except the camshaft so far. I was told by a respected Stude engine builder that the camshaft very rarely wears out and needs replacement, baring any catastrophic failure.

That being said, can anyone venture a guess as to what is an acceptable wear difference (in mm) from lobe to lobe on the camshaft?

I should add the engine/camshaft has 57,000 miles on it.

-

10 hours ago, Randy Atkin said:

Here we are some 60 years after the debut of the Avanti and brake pads, pistons, cylinders, etc are still available. How long will we be able to buy Cobalt pads - 5 years, 10 years? They could go out of business tomorrow. Then what? Something to consider.

A google search indicated Moss has been in business since 1921 but Anything is possible!

For me, brake pads are not an issue, but could be for someone who's Avanit is a daily driver and puts on 15K miles a year of stop and go traffic, a set of new pads will probably last me forever but not for everybody.

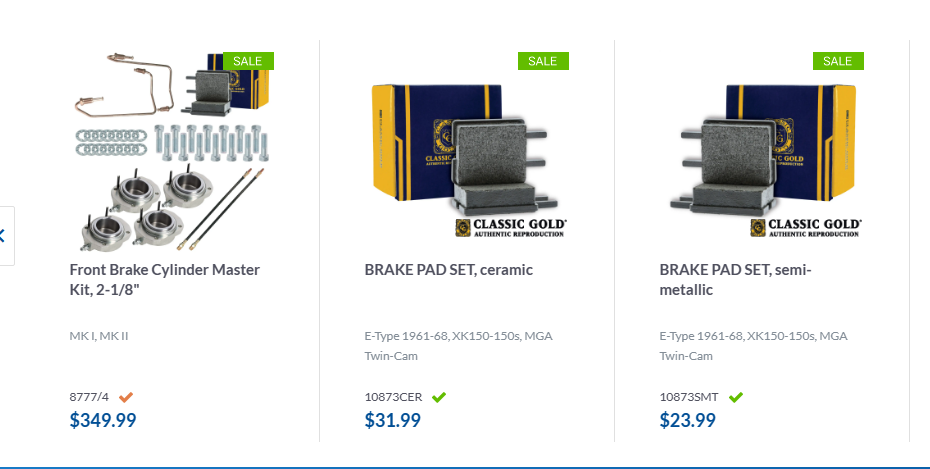

As another member mentioned, buy 2 sets of pads, they are very reasonable, $24 for semi-metallic, $32 for ceramic, should last a long time.

Many went to the Turner system which uses the aftermarket conversion brackets to mount the calipers and uses a single piston floating style caliper where as the original Bendix/Dunlop system uses dual calipers for each wheel/pad as do the new Cobalt calipers, which promotes more even wear and braking power it is said.

All in all, any upgrade to the original system is a plus, there will always be a down side to everything!

As always, I appreciate and respect anyone one's comments!

-

The shop I use is in Hazleton, Pa., not too many around any more like in the days when these cars were new.

The shop bored my engine to .030, the heads were already done when I bought the car in February but not installed, I ordered all the engine parts myself and I will assemble it when it comes back from the machine shop, the only other thing I will have the shop do is install the new cam bearings,,,,,,

-

I started a new topic to update my evaluation of the Cobalt calipers for those who are interested!

-

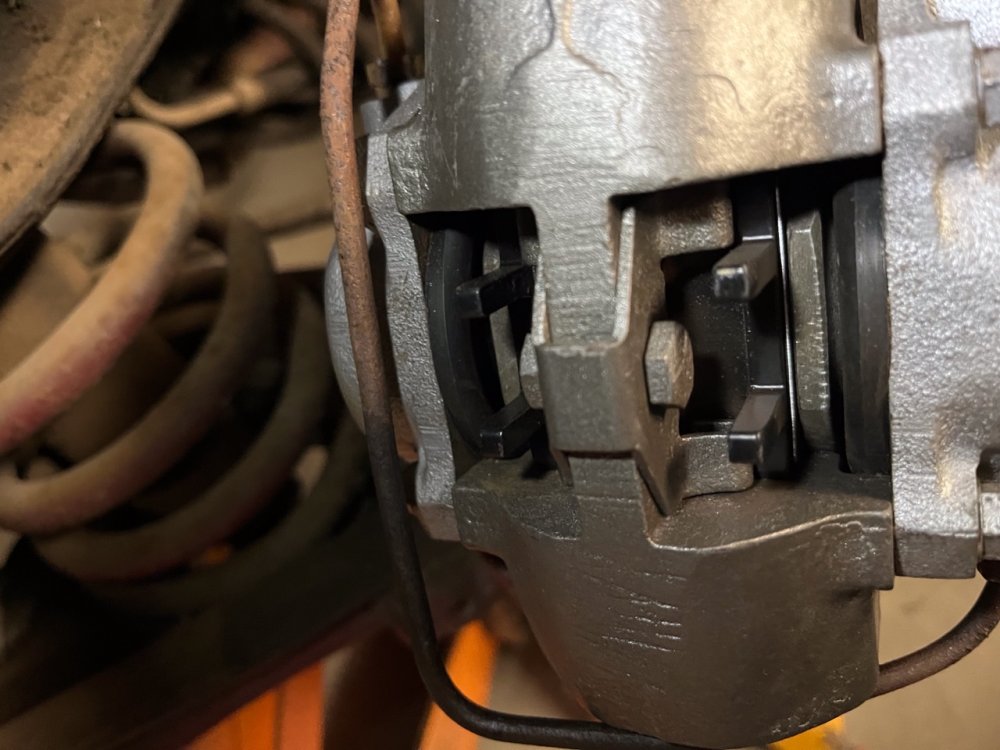

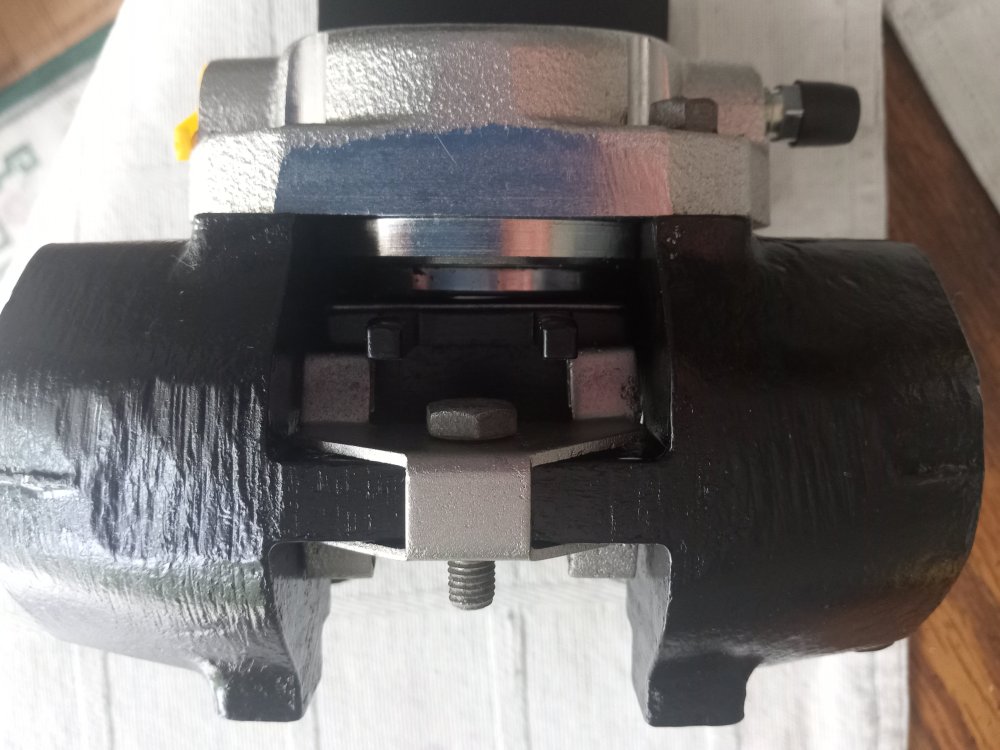

Now that I received the correct brake pads, I can show how things fit compared to the original Bendix calipers.

1st, the backing plate of the new Moss/Cobalt pads is much heavier/thicker than on the original pads, which is what Cobalt indicated is needed for their piston design.

2nd, the new pads are about 3+ mm shorter than the original pads which leaves a greater gap between the top of the pad and the silver metal “retainer” that you remove to replace the pads when needed.

3rd, the roll pins which are installed on the Cobalt calipers, which I originally thought needed to be removed for clearance on the mounting brackets, are there to keep the pad from slipping down in the bracket. That original thin plate needs to be removed as it would interfere with the new piston design of the Cobalt and the roll pins replace it.

I don’t know if that extra gap at the top of the pad would be a problem but I could either slot the silver retainer to move it down, slot the hole in the bracket and that would move it down, or glue an appropriate size piece of metal or other suitable material on top of the pad, and that would take up the gap. Also, it’s possible nothing at all would need to be done since when the piston (s) move out they will hold the pad from moving (I would think).

It would be some time before I can evaluate the braking power of the new calipers/pads, as my car is completely apart and the engine is in the machine shop.

Initially, for the price of $270 for 4 newly designed calipers, it seems a good alternative, for me at least, especially because I’d like to keep things as original as possible.

The car stopped fine when Stude made it new in ’62 so no reason it won’t now, I’m not a crazy driver and only drive my classic cars occasionally in the better months of the year here in Pennsylvania!

-

18 minutes ago, Nelson said:

The Stude pads are retained by a center pin on the piston which the Cobalts don’t have. I Imagine they will be fine as is. I think the center pin on the Stude acted to retract the pad with the piston. Most disc brakes just rely on rotor runout to do the same job…. I think?

Sorry, I assumed you were referring to retaining the pads in the carrier/mounting bracket once assembled, not the piston, so yes it would work like most modern disc brake systems, being the pad is free floating against the piston where as the Stude the pad was attached to the piston,,,thanks

-

43 minutes ago, Nelson said:

In looking at the photos of the parts, what retains the pad? Maybe those roll pins are there to keep the pads from going down too far during installation?

As my previous comments mentioned, I don't have the correct pads yet but my assumption is the pads would stay in place the same as the original Dunlop pads would, and as far as the pins, they are something that may fit into the Jag caliper brackets but not the Avanti ones and should/will be removed, they are only "pressed in" light duty roll pins, other wise the Cobalt caliper is the same,,,

-

1 hour ago, Nelson said:

Is the pad thickness the same on these versus stock or is it reduced to account for the thicker backing plate?

Also, I assume these will wear down to metal against metal where as the stock unit has a built in positive stop?

Looking closely at the Cobalt vs. the original caliper, it seems the Cobalt piston retracts (or is shorter or less deep) than the original piston so it would allow for a thicker pad than the original Bendix, so it would accommodate the thicker backing plate and provide the same, if not more, pad thickness (wear).

As far as, metal to metal wear, in my experience classic cars are not driven hard or many miles and in my case at least, I won't worry what might happen in 100 years; thanks for your observations and comments!,,,

-

27 minutes ago, Zedman said:

Hi Rick- The pistons on your Cobalt cyls are hollow, whereas original Pistons are flat, wide and solid. Stock pads are quite small. Are these pistons going to properly bear on the small 'Bendix' pads?

It's not a problem, if you go back and scan some of the previous comments, it's mentioned Cobalt calipers come with special pads to accommodate the different style piston so you don't use the original Bendix pads at all, unfortunately in my case, Moss motors sent me the wrong pads which will delay me a week until I received the correct pads,,,

-

6 hours ago, Dwight FitzSimons said:

6 hours ago, Dwight FitzSimons said:Yes they are the correct pads which should have come with the calipers, they can be bought in either ceramic or semi-metallic, their website does not state which ones are included with the calipers I purchased, semi-metallic are less expensive so I assume that's what they would have sent with the package,,, thanks

-

7 hours ago, brad said:

Did you not read where the pads have to be special and NOT the Bendix Type? Stock pads will NOT work with these pistons. You need the thicker backing plates of the new pads.

It is not an issue of needing special pads and me not knowing that, the correct pads are supposed to be included with the calipers and they were not, the pads they sent me (by the number) are for an Austin Healey.

Again, they send the wrong pads, see Dwight's post in which he shows the correct pads which I had also located on their website, I will have to call them on Monday (tomorrow) and have them resend!

CONNECTING ROD CLEARANCE

in 1963-64 Avanti

Posted

Trying to determine the connecting rod bearing clearance after I had my crank polished, shop said it was in good condition and only needed to be polished, not cut and use std. bearings.

Under the engine section of the workshop manual, if I'm reading the correct specifications for what I am trying to measure, it lists the connecting rod bearing clearance as to being .00025 - .00275 inch.

Is .00025 even measurable with plastigage, the green plastigage goes from .001 - .003 inch; or am I misinterpreting something here wrong?