-

Posts

72 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Rob Dudley

-

-

If you can't rebuild the old cylinder just get a new one. You're trying to save $150 dollars on your $20,000 dollar investment. The sleeves can and do slip and the time it will be tested is during an emergency stop. I just threw out a pile of sleeved cylinders that had slipped since the originals are available again. One of mine slipped just in normal use after being in use for a number of years. In new condition the originals do work very well although they won't dissipate heat as well as modern designs, allowing for fading during intense workouts.

Rob

-

sounds like dirty points in the regulator or a loose wire.

Rob

-

It was a kind of textured chrome. Kind of like a very fine wall spray-on texture that was chromed. Re-chroming it fills the low spots and is much more reflective than the original.

-

it's the part number of the x member.

-

The simple answer is NO. He isn't telling the truth. There were different engines as the R3 was being developed but that is another myth. the final engine was 304.5 single enclosed carburetor supercharged engine with special heads and other peripheral parts putting out an estimated 335 horse power in stock form.

Rob

-

It appears to be parked just right. Look to see if the right pivot is correctly rotated. I believe it can go in 180* off. Sorry, I can't load pictures.

Rob

-

No, It is just a coil on a curved magnet that moves the needle.

Rob

-

It is just a block off plate. The early engines had a neck there where you added oil. In the earliest engines the fuel pump was also mounted to the neck and a rod ran down to the camshaft to operate the pump. With the addition of the pcv system the breathers and fill caps were moved to the valve covers. The bolts screw into the block so you can go ahead and pull the cover off and paint it.

Rob

-

You need to narrow down where the noises are coming from. Can you get the noise by just revving the engine? It could be a bearing in either the rear end or transmission. It could also be a burned out muffler. Does it seem worse going around a corner? Lots of questions are left.

I have R3858.

Rob

-

2 hours ago, Kennie B. said:

Those numbers don't quite add up.

My car currently has the 3.73:1 ratio in the original Dana 44 axle.

At 3,000 RPM, the speedometer indicated 68 mph with the original Powershift transmission.

I just finished the engine swap that included a T10 transmission. The speedometer drive on the new transmission is set for a 3.31:1 axle which is what comes next. With that, 3,000 RPM indicates 82 mph.

For the record, the factory manual shows the axle ratios as; 3.07, 3.31, 3.73, 4.09 and with a four speed trans 4.55. That last choice requires a different differential. There are all kinds of ratios available for the Dana 44 so do not dispare. Jon Myers and Dave Thibeualt have gear sets as do Summit and Jegs.

Ken

Thanks for the numbers. Now I need to check my ratio and my tach. I have a powershift but that shouldn't make that much of a difference in engine speed. I am guessing that these numbers are for stock tires although it wouldn't make a difference one way or the other on indicated speeds (thinking as I type).

Rob

-

Mine has a 3:31 ratio and cruises at 3650 at 80. Yes it roars. We drove across Montana, Wyoming and South Dakota with it on the interstate. I think you should check to be sure of the ratio because the housings may be different. A good 4 wheel drive shop will be very familiar with these rear ends as they are common to Jeep. They will know what your options are and will have access to the needed parts.

Rob

-

I'm not sure exactly what your question is but you should start a new thread and add more information. What is the ratio now, what transmission do you have and what are you trying to achieve.

Rob

-

I like that idea a lot. I have a/c and it is a PITA to get to those nuts. I did find it much easier when I moved the radio out of the way, then removed the speaker which needed replacement at the same time.

Rob

-

I think Brad is talking about the rear drum in the transmission. If the throttle rod is not connected it will not allow the transmission to shift at the correct speeds. It might shift immediately or it might not shift at all. It could damage the transmission or drive train because of overly hard shifts.

Rob

-

Be sure the throttle pressure rod is correctly attached to the linkage and is correctly adjusted.

Rob

-

The valve needs to be put together with some movement. This allows the spool to send fluid one way or the other.The nut under the cap on the end of the spool bolt should be tightened just enough to cinch it up then backed off one flat.

Rob

-

Be sure the control valve is properly adjusted.

Rob

-

# 9 Avanti

-

the cross-over tube.

-

The heavier one goes to the regulator.

Rob

-

Since production ceased in December of 63, I will say false.

Rob

-

On 2/11/2017 at 9:08 AM, dynolou2 said:

Rob, did you use the front of the seat mount repair kit? We installed a set of the ones from Classic Enterprises on Al Basiles Avanti , they install fairly easily and add much needed support in this weak area. Lou Cote

The seat tracks were the problem, not the anchor points. The seats have been moved back an inch by adding an inch to the fronts and cutting the rear strap off and welding it back on an inch forward on the tracks. The front welds appear to be gas welded and were not correctly welded to begin with. One of them had failed.

I got the wipers done and the radio speaker replaced and working. When I tested the wipers there was a distinct clunk as they reversed. A little checking them found the mounting adapter screws were loose so I removed the motor and tightened them up with a drop of Loctite to prevent it happening again.

Now when I turn them on they won't park. They run until I turn the key off then stop where they are. I don't know what I did but it is quite perplexing. I checked the ground to the switch, even adding a second one. I opened the park switch and believe it is working but need to test it. Any other suggestions would be welcome.

-

-

Our trip to Kansas City brought about some new issues and highlighted some old ones. Coming across South Dakota a pheasant flew up and hit the windshield wiper as it committed hari kari. The strike left the right wiper halfway up the windshield. It turned out to have spun the splined hub on the pivot, stripping it. The driver seat had a broken track mount and the front speaker didn't work. Now is a good time to do some maintenance (with 2 ft. of snow on the ground), so I started with the wipers. I managed to get the pivot out around the air conditioner and since pulling the seat made it easier it came out too. I was able to reach the wiper motor and left pivot from the drivers side and by pulling the heater valve loose I worked the control rods out the passenger side.

After checking the wiring on the speaker I determined the speaker was not working but I could hardly see it, let alone reach it. I unbolted the radio and pushed it in on top of the A/C. Getting my fat hand in through the opening was tough but I was able to reach the speaker retainer nuts and that allowed me to remove the grill and pull the speaker through the dash. I ordered a new one from Dan Skidmore. With the pivot out I was able to pull the splined hub and determined that it is the same as one on the pivot of a '63 lark I had scrapped. After removing the old hub, I filed the peened axle tip smooth and was able slide the new hub on and re-peen the end of the axle. It looks good. Now to try to get it all back in.

Rob

64 Avanti resto mod

in 1963-64 Avanti

Posted

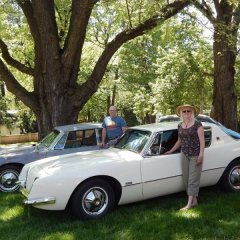

I met the owner and saw the car several years ago when I bought the original R1 and powershift trans. that was taken out of it. I was very impressed with the car. He was someone who like cars and modified them to his liking. He said he just didn't like it in white. The car appeared well done and very striking. I believe he had just retired and seemed to know everyone in town. I am sorry to hear that he has passed.

Rob