R5335

AOAI Forum Members-

Posts

22 -

Joined

-

Last visited

Previous Fields

-

My Avanti

64R-5335

Recent Profile Visitors

985 profile views

R5335's Achievements

-

Thanks for fixing

-

Based on Bob Johstones Studebaker Resource website, it would say False. According to his information, the front was raised 3". At least 3" above the front wheels and the front fender. Newman - Altman spent 1965 re-engineering the car for the GM engine, upgraded upholstery and other amenities. There were no official 1965 models. Any cars titles as a 1965 are rare, most are regarded as '66' models. In '65, the R-series engine options under Studebaker also disappeared and the vehicle numbering system went from "R-xxxx' to 'RQA-xxxx'. They adapted the GM 327 Cubic inch/300 HP through a custom bellhousing and coupled it to the existing Powershift (FMX type) transmission. The remainder of the car stayed, as Studebaker had produced it, with the exception of the emblems.< The installation of the new engine required the body to be pivoted upward in front, in order to accomodate its dimensions. This was accomplished by using varying thicknesses of steel shims along the frame mounting points. The resulting, additional, three inch gap between the fender and top of the wheel was remedied by installing filler pieces at the top of the wheel opening.

-

The following is taken from Bob Johnstone's Studebaker Resource Website. My understanding was that the Avanti II, ie post 1965, the body was raised about 3" to accommodate the SBC 327. Similarly, I was informed the even the Studebaker R3's, the bodies were raised about 1.5-2 inches to accommodate the R3 supercharger airbox. I can attest to that, my 64R5335 was modified with an R3 type airbox but it rubs against the underside of the hood, the body wasn't shimmed up to accommodate it. I think the R2 airbox is lower in height and so it didn't require shimming. Newman - Altman spent 1965 re-engineering the car for the GM engine, upgraded upholstery and other amenities. There were no official 1965 models. Any cars titles as a 1965 are rare, most are regarded as '66' models. In '65, the R-series engine options under Studebaker also disappeared and the vehicle numbering system went from "R-xxxx' to 'RQA-xxxx'. They adapted the GM 327 Cubic inch/300 HP through a custom bellhousing and coupled it to the existing Powershift (FMX type) transmission. The remainder of the car stayed, as Studebaker had produced it, with the exception of the emblems.< The installation of the new engine required the body to be pivoted upward in front, in order to accomodate its dimensions. This was accomplished by using varying thicknesses of steel shims along the frame mounting points. The resulting, additional, three inch gap between the fender and top of the wheel was remedied by installing filler pieces at the top of the wheel opening. The 327 engine & 2.5" exhaust manifolds into 2.25" exhaust pipes remained throughout 1969 production. It in 1970 the 350/300 was installed and the exhaust manifolds went to 2" with 2" exhaust ( reportedly to be much easier to install ) . Again the 350 was coupled with the original Powershift (FMX) transmission or T-10 four speed. The first 350 equipped Avanti II was RQA0315. Ref.. The first 400 cubic inch engined Avanti was the first 1972 Avanti...RQB1801. That was with a 2-barrel carburetor. The first 400 cubic engine Avanti with a 4-barrel carb was RQB2050 (1974 model year). Ref.. For those that want a trivia point, the "II" in the Avanti II emblem was made from the Lark's V-8 emblem, by cutting off the first 2 characters of the "VIII" - (VIII -> II) Nate Altman and Molded Fiberglass Co (MFG) Page 1 Page 2

-

My first purchase was a 63 Avanti 63R-1220. I knew it needed help but got a real big surprise when I tried to remedy the braking issue. The car had no brakes, I figured this could be an easy fix. Well, first, someone in the past replaced the Front disc brakes with drums? So I removed the drums to install the Turner disc brake setup and there was no hardware! No shoes, no springs, no nothing other than a clogged up rusted wheel cylinders. So decided to check the rear brake drums, dang same thing. Nothing. This car currently going under a major restoration, engine and transmission at the machine shops currently. The second purchase was a 64 Avanti, R-5335. The car looked Ok until I got underneath and started digging around. Someone tried to turn this R1 into a pseudo R3. First they replaced the steering system with a rack and pinion unit and replaced the suspension with a tubular setup. Turns out the rack and pinion unit interfered with the oil pan. One day trying to figure out why the pan leaks, I noticed a crack. I took a Sharp scrapper and started picking at it and only to find out the entire pan had been coated Bondo to hide the mess. In order to get the pan in, they had cut the pan up into several pieces, brazed it back together and to hide the deed, smothered in Bondo. The brazing job was not very good and had several leaks. Add to that the pan is all banged up I guess in the effort to get the engine in. Then the suspension system is a mess. I'm working this issue now. No way to get caster, camber and toe-in correct. Looks like I'll need shims to straighten this out. As far as the engine, the distributor was a wreck. Some left over Chrysler 1980's electronic unit. I've tried to remove it and replace with a new Petronix but can get the unit out. Something internally keeping it from being pulled up. I've had several folks try and no way. The engine will need to come out to fix this along with the pan. Then, there is a "Spider" gear inside the distributor that has a key to keep it in sync with the distributor shaft. Well, they used a wrong key, it kept falling through. When it did, I'd lose timing and had to retime it. Eventually figured this out and place a proper key in place to hold the spider gear in place. Finally, the engine runs like a champ but still dealing with the steering/suspension issues and eventually the pan issue. Currently, stopped 99% of the pan leaks with a metal epoxy called Belzona.

-

Enjoying this discussion. So to add to this line of thought. Could you use a 570 head, with the supercharger but swap the pistons out for 1/2 dish pistons. I tried doing some calculations and with a std steel head gasket, I estimate the compression ratio of about 9.5. Do you think that would work with 93 or 92 octane gasoline? My 64 R5335 is an R1 block, with Hawk heads (casting 535976), a supercharger, and full dish pistons. That's how I purchased it. I estimate the compression ratio of about 8.5. My compression checks indicate an average of 150 psi in the cylinders which I think confirms that lower ratio. I was toying with the idea next year to replace those heads with 570 heads, std steel head gasket, and swap the pistons to a 1/2 dish piston to raise the ratio and get some horsepower out of it. I'm using 92 Octane currently without any ping but not surprised.

-

Just wanted to add to this discussion but hoping others can help me with a very similar dilemma. So I sent my Brake booster out to be rebuilt and purchased "Another" master cylinder. Bench bled the master cylinder. Installed the rebuilt booster and the new master cylinder. Plugged both the front and rear brake ports so only the master cylinder is connected to the booster, the rest of the system is isolated. With the engine off, pumped the brake pedal, hard as a rock, no movement. Now the fun. Start the engine, pump the brakes. Expecting not to see anything different. However, not the case. When I step on the pedal, it sinks and the engine loses vacuum and stalls! So shut the engine off, checked the check valve, it works as should. Tried again, same issue, engine loses vacuum and stalls and pedal sinks almost to the floor. So went back and tried another master cylinder and same thing. My thought is there is something not correct with the rebuild, the key is why should I lose vacuum when stepping on the brake. Prior to replacing the brake booster, the brakes worked fine! I changed out the original booster and master cylinder as I had seen brake fluid leaking out between the original master cylinder and booster and was concerned that fluid may have gotten into the booster which may eventually make it fail. Feedback from the rebuilder was that was the case and he observed fluid inside the original booster. As one last comment, is there an alternate brake booster replacement for the original booster? A more later year booster from a chevy/ford/chrysler that would work? This is getting frustrating.

-

I have a 64 Avanti, when these air ducts were first introduced. As someone informed me when I inquired on the forum, they provide little cooling to the transmission shifter in reality. I've driven mine around with new hoses and the air that exits the hose is just a wisp at best. As far as hose replacement, I found that the hose used for water supply to your washing machine was a perfect fit, it's plastic so won't deteriorate like the originals, they're plenty long enough and will need to be cut to length, they have the same ID and they're inexpensive. There are some foam gaskets that the hoses go through, 2138-71 that also deteriorate over time. I found some foam with a tacky backing on amazon that I cut out to replace them, again a synthetic that may last longer. However, all said and done, as I mentioned, at 65 mph, very little air blows through. I'm toying with the idea of making a small scoop for the air vent cowling in front of the window. Something simple out of sheet metal about 3/4" high, maybe it'll catch enough air flow to make these functional.

-

Mark, I hadn't seen anything on this since you last wrote on 11/10/24. So I too have just run into this issue. I'm hoping you found an answer. My story is similar. The original dual master cylinder was leaking and some fluid was getting into the booster. So I replaced the master cylinder. However, my mistake, I extended the booster push rod to what the manual said to 1.25 inches. Didn't take long to burn up the calipers. So replaced the calipers, had the rotors turned. Reset the push rod from the booster to match the new master cylinder, in my case 1" (actually 31/32). Then off I went and for a few rides ok. Shortly thereafter, pedal was very hard to push and brake the car. OK, videos and discussions with folks says it's a bad booster. So, sent that off to have it rebuilt. Report back was yes brake fluid got in and diaphragm was cracked and the wrong check valve. So, finally got that back. Put it all together, bench bled master cylinder, bleed the system 3 times. Now when the engine is off, brakes are hard to push as would be expected. However, like you, now when I turn the engine on, brake pedal goes to the floor! On top of that, the engine stumbles, loses some vacuum, about 5" Hg. Bleed brakes again, no change. Talking to the fellow who rebuilt the booster says it's a bad master cylinder. Damn thing is only a few hours old. I'm using DOT 3 fluid if that means anything. I'm at a loss as to what the issue is hence why I read your forum with great interest. It also appears when doing a search on the AOIA and SDC forums, this has been a familiar problem with a fair number of people.

-

very nice job. excellent work

-

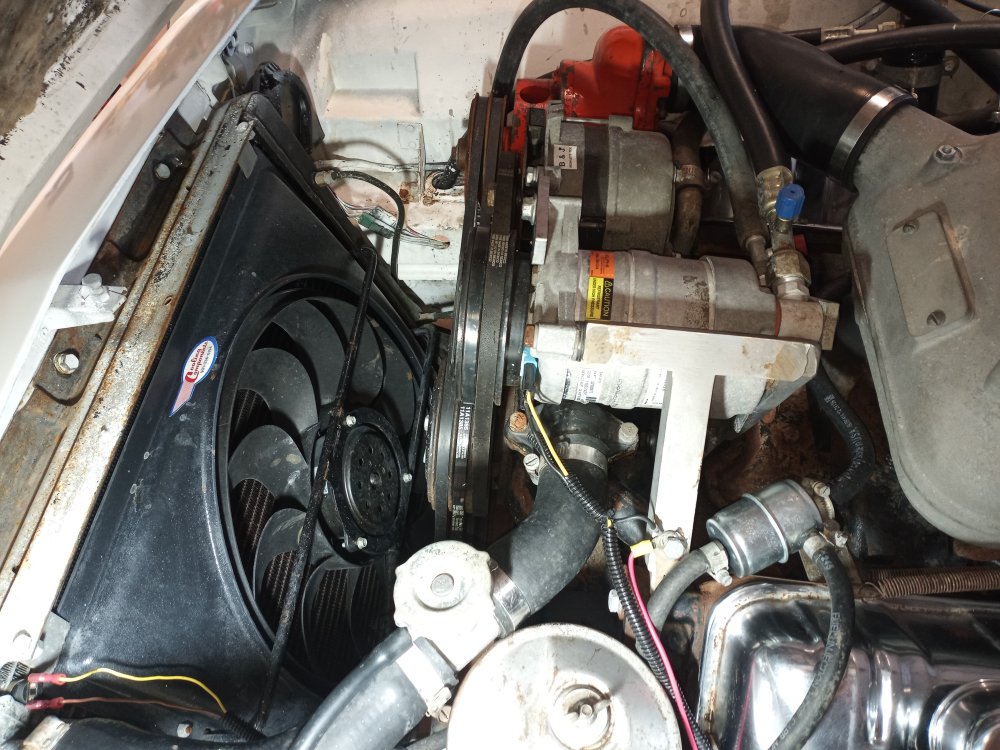

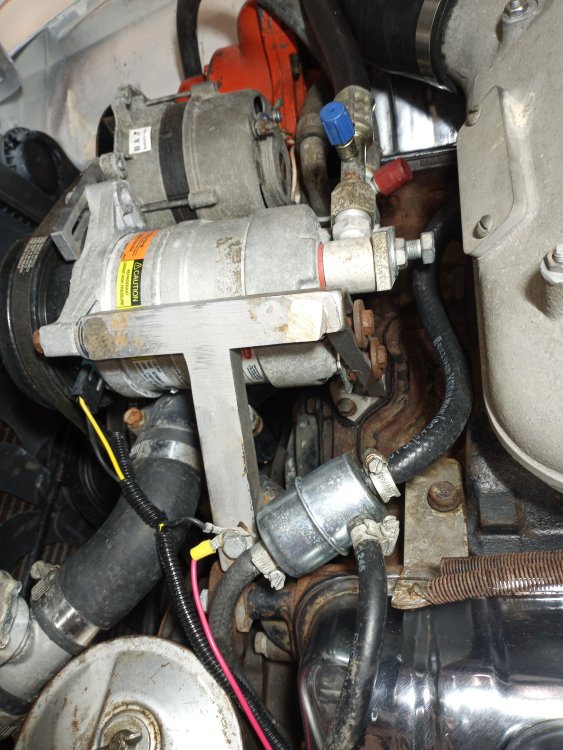

I'd like to know more about the electric steering. I too have an R2/R3 with AC. it was modified many years ago by a previous owner. However, my car utilizes a hydraulic power steering unit. SO the pump is driven by the engine. Therefore, my setup is very congested and one of the brackets rub up against the bottom of the hood. So as I noticed from your photos, you had the ability to move the alternator where the power steering pump was, leaving plenty of room on top for the AC unit. I am really unhappy with my power steering setup, it's another mod and has caused many other issues below, it's a rack and pinion unit but interferes with the exhaust and oil pan. So the electric steering looks like an opportunity to fix a lot of problems.