MarcD

-

Posts

16 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by MarcD

-

-

HI Jeff

I'm in the same boat (to be more precise, an early '66 Avanti II). A previous owner replaced the original trunk release cable assembly with a generic throttle cable...did some fiberglass work around the attaching point below the left armrest with well nuts. Didn't work well, and although I've sprung for the correct cable and handle, I've got no idea what the escutcheon and nut even look like, let alone where to buy them.

Have you had any luck with this? Sure would be nice to find a few pics of an original fitting, but no one seems to highlight that part of the car,

Marc in SF

-

I have a question about the clutch linkage on a manual transmission-equipped Avanti; I'm posting in the 63-64 forum because I think the vast majority of stick-shift Avanti's are Studebakers; not a lot of Avanti II's out there, and even fewer m/t cars.

I'm converting my '66 Avanti II from automatic to a T-5 manual transmission, and plan to use the Chevy T5 hydraulic slave cylinder and throwout assembly. I've acquired all the NOS Studebaker parts needed for the clutch actuation from the clutch pedal (including the shaft/manual brake pedal, various rods/clips/boots/shims/seals) to the chassis-mounted bell crank/pivot arm.

On the stock Avanti system, a rod connects from the bell-crank/pivot arm to the throwout arm to actuate the throwout bearing. What I need to know is what is the total length of travel of that connecting rod needed for full clutch operation. This would probably entail having a manual-transmission car up on a lift with one person depressing the clutch while another person measures the distance the rod travels from engaged to disengaged.

I would then use that measurement to select a master cylinder with matching stroke length/diameter to move the Chevy slave cylinder the correct travel.

I'd really appreciate any info provided!

Thanks,

Marc

-

Hi Bob

Thanks for the quick reply and words of advice! Your beautiful work was part of my inspiration to pursue the conversion, and I also reviewed the Spring/summer ‘09 article.

My ‘66 (80k miles)actually has the original, somewhat tired 327, which I plan to retire to a display stand and replace with an ‘89 Camaro 305/World Class T5 driveline currently residing in a friend’s garage. I know the 305 gets no respect with the hot rodders, but my dad had an ‘89 Firebird with same driveline, and it had enough suds for me!

The big question is will the shifter align well with the console opening? The Camaro WC T5 is the “furthest back” shifter ‘box (compared with the S-10 and Ford T5), but I do believe the Camaro used the canted bell housing, with the shifter assembly aligned straight up. May I ask what your concerns were about that setup?

I believe the critical dimension will be the distance from the bell housing end to the centerline of the shifter itself. The Avanti magazine article is a T-56 behind a Stude engine with an adapter plate; that may not be the same set of dimensions as an SBC Avanti II, like ours.

Do you happen to know what that bellhousing-to-shifter CL length is on your T-56 setup? That would be REALLY good to know!

My car currently has the Stude tapered axle open diff rear end with 3.76 (I think, been a while since I looked) gears. Your advice about a posi, along with the notorious tapered axles on an old car has me considering other options.

I await input, comments and laughter as appropriate!

Thanks,

Marc

-

My ‘66 Avanti (327/Powershift automatic) is pleasant to drive, but I know it’d be a blast with a manual trans, preferably a five-speed. I’ve seen articles on converting Studebaker Avanti’s using t-56’s and six -speeds, but i prefer the lighter and more compact World Class T5. I’ve converted early Mustangs and a Datsun V8 240Z using T5’s; with a moderate power engine (and a 68 year old driver) they’re plenty stout. I’m thinking a bellhousing/trans from a late ‘80’s Camaro/Firebird would be a good bolt on to the existing Chevy engine, but not sure about shifter location or rear trans mount.

I’ve accumulated all the manual shift pedals and clutch linkage parts needed, but would really appreciate hearing from someone who’s done this installation. Past experience tells me there’s lots of details involved and parts choices to make.

Thanks!

Marc

-

Greetings from California. I live in the City and County of San Francisco, which requires front plates at the request of traffic camera contractors, who need the front plate image to extract the Court fines and fees.

My ‘66 Avanti II has the front plate attached to the passenger side bumper “end iron”, and while I wish it wasn’t necessary, it sits back of the bumper and is pretty unobtrusive.

-

What’s an “a11” number?

-

Thanks. pb.

Maybe Studebaker (Or the Feds!) knew the tubular rear crossmember would rust out!

I’ll check my 1966 Avanti II (RQ-A0090) and see if the number’s there.

md

-

Hoping this thread isn’t too old to ask, but has there ever been a final, definitive answer to the question of the Avanti rear frame crossmember stamped with a hidden serial number, like the Lark and others?

How about The Avanti II? They had no frame serial number plate on the right frame rail like the ‘63/‘64 cars; just the serial number plate riveted on the drivers side hinge post.

Thanks,

Marc

-

Preparing to replace the hog troughs/torque boxes in my ‘66 Avanti II and considering the options.

curious if anyone in Northern California (SF Bay Area) has done this, or any comments about the multi-section kit(s) available.

cheers

Marc

-

Hi Mel

Thank you as well for the welcome and tips; I’m already in process of installing the Turner Brake kit, and will certainly ponder long and hard before diving into the dash.

Looking forward to reading your magazine articles. My PO is a great guy and included dozens of back issues with the car, and the manuals arrived from Stephan Allen today...lots of study ahead!

Cheers,

Marc

-

Thanks for the info and warm welcome, Bob!

Small world; I ordered manuals from Stephan Allan last week and the very helpful and knowledgeable young man on the phone was...Matt! Nice to see the flame being carried forward; I had to practically drag my kids to the DMV to even get them to drive!

RE: the white-red wire damage; that wire was completely encased within the harness and not in contact with the manifold. The damage you see must be entirely caused by shorting!

Thanks again for the forum tips; I’ll follow up and keep expanding my knowledge base and hopefully contribute from my past mistakes..uh, experiences.

Regards,

Marc

-

Thanks, Avanti83.

To clarify, “starts and drives” refers to starting the engine and driving the car off the trailer into the garage. The car was in storage for several years, and brakes are next on the repair list!

i believe the car originally had a voltage regulator and was converted to single wire by a PO (Previous Owner); there’s a receipt for a new alternator in the file included with the car. I’d mentioned other electrical bodges...there’s an unused multi-wire connector near the battery that was most likely the voltage regulator location.

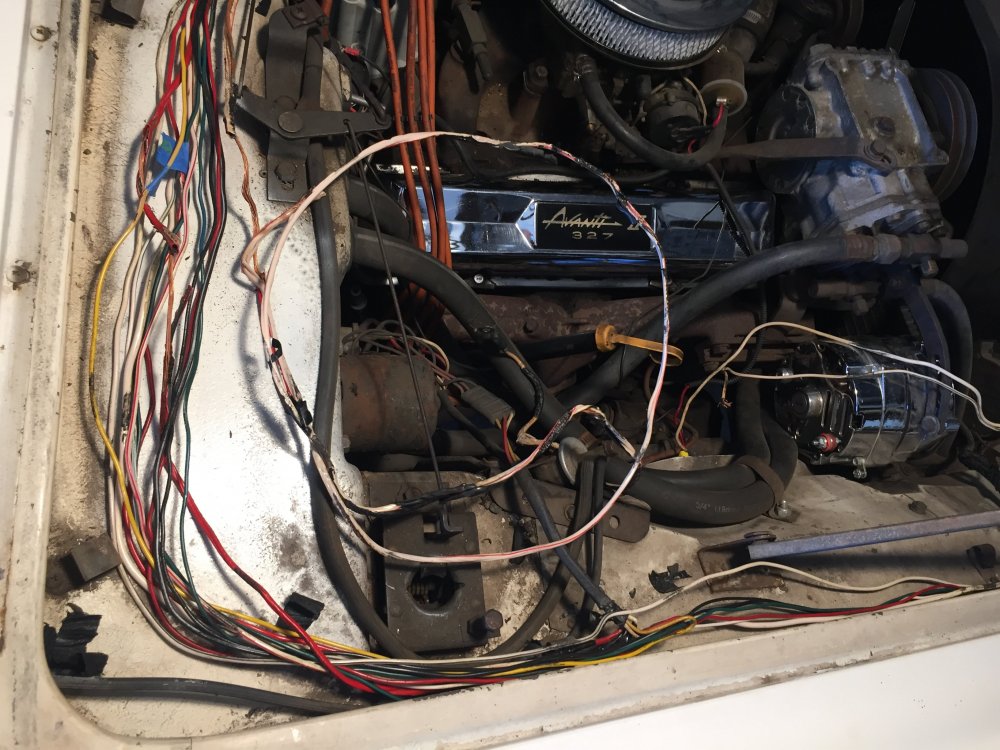

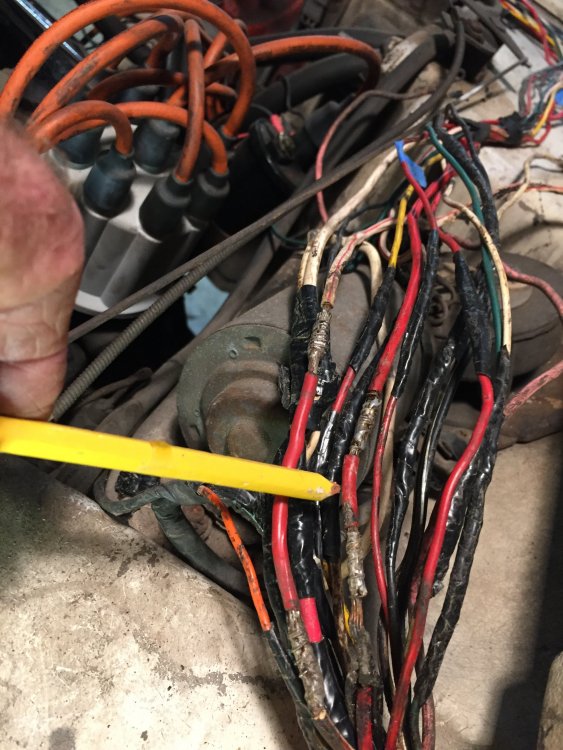

Here’s more pics showing an overview of the harness (the looped wire separated from the rest is the white-red to the alternator), a section of damaged harness before dissection, and the firewall bundle ‘o splices just after unwrapping.

The under dash wiring looks ok, so hopefully I can re-wire from the firewall splices. I’ll be sure to include a new fusible link at the starter relay, and maybe at the alternator post as well. Repairing vintage tube guitar amplifiers is another hobby for me; I’ve got a good iron and rosin-core solder. Good call on the cold solder joints, by the way.

I’ll also plan to test the repair BEFORE re-wrapping the harness!

-

Thanks for weighing in, Silverstude; repair splices may well be what they are. That’s some serious technique: the stranded wire ends appear to be wrapped in solid core wire and heavily soldered. An odd thing is that it’s only the two affected wires plus the white 12ga ground wire that have the extra wire, and it’s red insulation on the “added” wire on all three. That would be an poor place for fusible links, as it’s buried deep in the harness, rather than out in the open where they could be serviced.

I mentioned in my first post that the vinyl harness wrap in this area appeared to be pretty original....the nonstick tape was the same material as on the rest of the harness, the weathering/dirt/crud was no different and the tape wrapping itself looked untouched. If this is a repair, it was done a long time ago and the entire harness section was rewrapped by a pro!

I sure don’t expect anyone to cut open their wiring harness to see if this is normal, but I wonder if anyone else has knowledge of the factory wiring procedure.

-

I think I’ve figured how to upload pics, so here’s two shots of the rats nest uncovered near the firewall. The pencil points to what I think may be fusible links spliced into the two burnt wires in question. If that’s what they are, I’m wondering why they are still intact with all the mayhem in the rest of the alternator-to-starter relay circuit.

if they’re NOT fusible links, what the heck are they?

-

Hi! I just acquired a 1966 Avanti II (RQA-0090); the car was in storage for a number of years and has more that a few issues to work out, but I'm semi-retired and have the time and interest to pursue solutions. I've ordered shop manuals and have the car up on jack stands in the garage for assessment.

The issue I'm currently dealing with involves the wiring harness. A previous owner had installed a single-wire alternator, and although the car starts and drives, I noticed semi-melted insulation on the white-red tracer 12ga wire connected to the alternator. This, along with evidence of other wiring bodges, led me to inspect the engine compartment harness a bit closer.

Whoa. I found the vinyl wrap to be burned through along several areas, including the sub-harness that leads to the starter relay. Quickly disconnected the battery, and started stripping the harness wrap. It appears that the white-red wire and plain red wire (both 12ga) both got pretty hot and melted through their insulation in many areas. Doesn't look like adjacent wires were damaged. While I don't have the factory wiring diagram in hand, a few links I've found indicate these wires run from the alternator to the ammeter (White/red) and back to the starter relay (red) and eventually to the + battery.

I've stripped back the harness wrap to the firewall and was astonished to find tape-wrapped splices on almost every wire in the harness, with some pretty creatively soldered splicing on the red/white wire. Plan to look under the dash and try to assess the condition of the wires all the way to the ammeter...will practice my yoga first. Really hoping to not have to pull the dash board, but that's probably inevitable.

A few thoughts here:

First, how and why did this melt-down occur? My guess is that the alternator was initially mis-wired during "conversion" and cooked the wires. There's a 12ga plain white wire to ground at the alternator (ah, yes a fiberglass car!) and reversing those two would do the trick in short order. There's supposed to be a fusible link on the red wire at the starter relay that would burn out, but I don't see it.

Second, hopefully, the damage was contained to the two wires under discussion, and I won't have to replace the entire harness (I ordered non-stick vinyl harness tape already). I'm hoping I can just replace the affected wires and re-wrap the harness. I've looked at a few posts in this forum and several people have just installed a new generic 24 circuit harness...rather not re-invent the wheel.

Third, is the "bundle o' splices" at the firewall really the way the factory built this car? The harness wrap at that point looked pretty original. I've owned many '60's era American cars and it's not uncommon to have a bulkhead multi-connector at this point to ease assembly and servicing, or just pull the whole harness through a big grommeted hole in the firewall. This is really amazing!

Great car, great forum, great people! I've wanted an Avanti ever since my dad declined my recommendation and bought a Riviera in 1963...wish he was still around to see this car!

Comments will be appreciated!

Cheers,

Marc in SF CA

Vendor question

in 1963-64 Avanti

Posted

Has anyone had an experience with a vendor named “AvantiParts.Biz”? They list a physical address in Morrissville PA.

The site has a very attractive price for a particular Avanti part I need, but I’m getting no repose to phone calls, and haven’t seen them mentioned here.

Any info would be appreciated!

thanks,

MarcD