SBCA96

-

Posts

518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by SBCA96

-

-

I got the rears on, plumbed and bled. Took it out for a drive tonight. WOW! I STOOD

on the pedal and could not get them to lock up. The car was stopping SO fast that the

passenger seat would fold forward. I think I need shoulder belts now!

Tom

-

I've been trying out some different wheel and tire combinations because there isn't much available in good performance tires in 15". I've decided to install 16x7 wheels with a 4" back spacing and P225/60R16 tires. The test rim and tire works OK with about a 1/4" of clearance from the rear inner wheel well flap. The front rubbed the frame on the drivers side if you locked up the power steering all the way right. I can add some material to the right steering stop to prevent this if I want to, but I don't see myself locking the steering up all the way. The 16" tire diameter is almost the same as the orginal P205/65R15's so I shouldn"t have trouble with the speedometer. Tried to mount 17x8 rims but it wouldn't fit on the rear, too wide, will try to find some 17x7's next.

I currently have 17 x 8 and it looks like I could have got away with a 9 or 10 wide. What frame does the

Avanti you have ... have? It must not be the Lark type.

Tom

-

My 5.0L is still strong so I'm waiting, have a LT1 with a 700R4 that I will replace it with one of these days.

Have any questions with that LT1, give me a holler ... I am pretty versed in them.

Also I am doing a swap into a 78 Camaro which should be simular.

Tom

-

Found a site for viewing custom wheels on a Avanti.

Does this ONLY show rims that will FIT an Avanti? Most the styles that I wanted would not fit on

an Avanti, and the styles that would fit looked horrid. Which is why I got the 8" Cobra wheels.

Tom

-

You should consider marketing the conversion. I know at least one who would be interested.

Paul

And who would that be? .. lol! Well .. I am certainly considering that option, the setup will be featured in an

upcoming Avanti club magazine, so for those of you who are members like myself, you will get this set to

your door soon. I am looking for input, and would also like to hit up SDC for feedback. If I know that there

is enough interest, then perhaps brackets are in my future. We shall see. I still have yet to receive ONE

Email from any interested parties. Not even for Info! This forum in amazingly dead. I actually hear some

crickets chirping when I log in...............

Tom

-

Tom,

I'm running 15" Steel Wheels from a Lincoln Towncar(early '90's) 6.5"rim width and the offset is ~0.5" farther out. Will you be at the Griffth Park meeting the 18th? Would like to see your efforts up close.

Chuck S

Cool .. so then this would return the wheel back to the correct "center" position. Good to know that

there are rims available to use the stock hubcaps. For the most part it can be turned back to stock.

The mod of the hub is "kinda" permanent, because of the larger stud. Granted you COULD still use

the drums drilled out to fit the larger shoulder of the stud. I dont see getting the car to that meet,

I currently have the rear brakes apart, and even if I got it back together in time, I wouldnt trust the

rest of the car to make it the 3 hour drive.

Tom

-

I need to check the fitment of a stock Studebaker wheel on the new brake setup,

but I am pretty sure that it WILL NOT fit, due to the caliper being out farther to the

wheel. This brake setup would require upgrading to wheels that fit a 1994 to 2004

Mustang. This can be viewed as good OR bad depending on your perspective. I

see it as GOOD, since during my search for wheels for my Avanti (over 10 years)

I couldnt find anything that looked good. They just dont make nice wheels in the

stock offset, at least not that work well with the design of the Avanti. Two things

I need to check on .. one confirming that the stock wheel fits or doesnt fit, and then

two what steel wheels are available for a 1994-2004 Mustang. I am pretty sure

that the base Mustang used steel wheels, and they should be 15 inch. Technically

that would mean the stock Stude hub caps could be used. I will check with my

Mustang buddies and see.

Tom

-

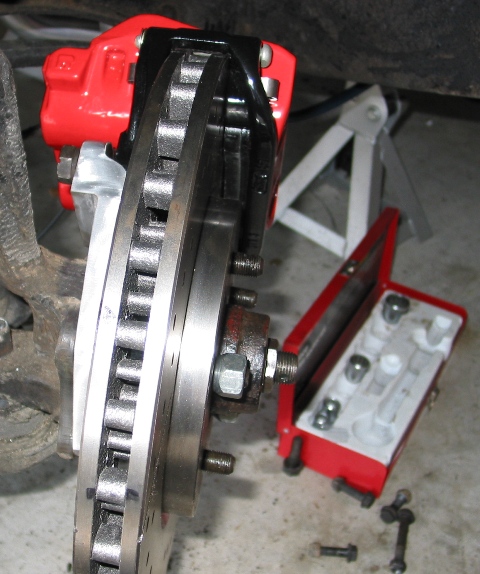

I thought that I would share what the Cobra brakes will look like, the calipers

come in both black and red (that I am aware of) and are actually 2 piston, not

4 piston like I had originally mentioned (thanks Ed and Eric for setting me

straight on that!). I got confused with the Baer 4 piston setup that my friend

had converted to (which got me the GT brakes!). If memory serves there is

an 8 piston caliper also available, but thats CRAZY talk!

These images were "borrowed" from http://www.edbert.net/brakes.htm .

After doing brake pads on my 1993 Camaro Z28 for the last 10 years, I had

thought that the Stude hubs could be modified to allow a "slip-on" rotor to be

used (like most newer cars). After finding out that Ford still used the same

bolt pattern as years ago, I knew that the Ford rotors would fit. After getting

Ed's brakes .. it all came together. When looking for the dimensions of the

angle of the caliper position, I came across "Mustang Steve" who makes a kit

that allows the installation of Cobra brakes on a first gen Mustang. It was his

website that I got the angle I needed. He was also very helpful by telling me

that Ford still used SAE flare thread (http://www.mustangsteve.com/).

10 inch rotor compared to the 13 inch Cobra:

Other assorted views :

Tom

-

I must also mention that "Bobby" the machinist thats been doing all the work for

me after hours, has been absolutely wonderful. If it wasnt for his patience with

the sometimes last minute and "on the fly" design changes this wouldnt have even

happened. Even the slight "correction" that we had to do on the rear brake caliper

brackets he didnt cringe (much) at. Thanks Bobby!! You dah Man!

Tom

-

After jacking the car up so that the wheels dangled, I figured that THIS would be

the "Worst Case" senario for the rubber brake hoses. I would end up trying quite

a few different locations and angles of the hose end before decideing on the best

position. The hose needed to be able to flex without rubbing anything throughout

the travel of the suspension and the turning of the wheel. What a pain! I found

that the stock Mustang brackets needed to be 90 degrees from what they were.

So I cut off the "business end" and then bought some steel stock. I wanted to use

the existing holes in the frame to bolt it down and locate it so that it wouldnt turn.

Here they are!! :

I dont know how to weld, but the supervisor of the machine shop will weld simple

parts for fast food fries. These cost me a large fry from Mc Donalds. This next pic

shows WHERE these go, I bet now it makes sense.

A close up ... pretty aint she?

And of course one for the other side as well :

The hoses dont contact anything when the wheels turn back and forth and the only

modification to the hose was an adapter fitting on the DRIVERS side to turn the

larger flare to the size Studebaker uses. Strange, but the PASS side was the same

size as Studebaker and didnt need to be changed. The wrench needed to tighten

the hose was a metric, but the flare was SAE - go figure.

My dad and I drove around and the brakes worked AMAZINGLY well. I had hoped

for an improvement, but there is NO comparison. Granted the old brakes were in

pretty bad condition, but the addition of a vented rotor will help cooling. I plan on

switching to the 13 inch Cobra brakes as soon as I get my tax refund. My dad

wants the GT parts for his Avanti.

Is anyone interested in something like this being marketed? I feel that by using

the original hubs, it really reduces waste, and doesnt require buying hard to find

rotors or using sleeves. Not to put down the great work that others have done to

keep Studes on the road, but I think there is always room for another viewpoint.

Shoot me an email if interested : sbca96@aol.com

Now I am working on the rear disc setup ... the brackets are done, and on the axle

and I am modifiying the hubs with the Dodge wheel studs. The outer dia of the hub

doesnt need to be machined down, because the inner dia of the Mustang rotor is

larger then the front and the Stude hub is smaller - perfect fit. The rotors actually

fit fine, but its recommended to have at LEAST 8 threads of contact on wheel studs

and I was at 5 with the stock length studs. I ordered the stock Mustang rear hoses

for the setup, because I didnt get those from my friend. I was happy to find that

Autozone includes the banjo bolt in the hose kit. Before you laugh, they are nice

hoses made by Wagner. Now I have to figure out the plumbing, once I get all the

wheel studs in ... had a mishap with one of the 5 studs I COULD get (damn the

StupidBowl, most the autoparts stores closed early today!), it contacted the socket

that I was using when pressing the stud in, and ruined the threads on the stud.

GRRRRRRRR!

Oh well .. gotta buy 6 tomorrow now.

Tom

-

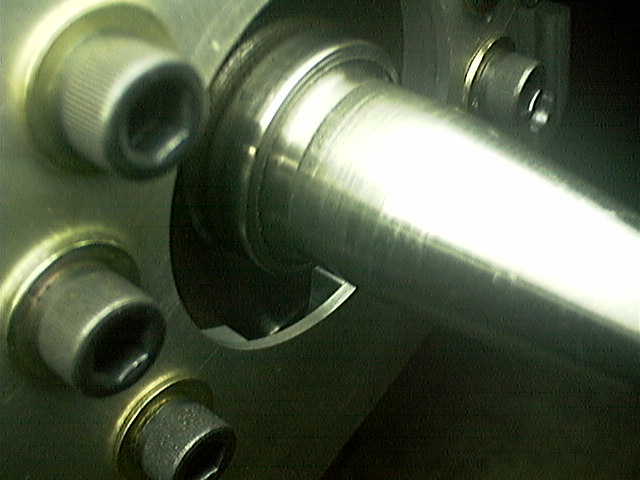

Masonite just doesnt compare to the look of machined aluminum. My work has a

lot of odd sized 6061-T6 scrap laying around, and even though my first choice was

to go with 7075-T6, you can not beat the price of free. Doing a comparison in the

strength of each, and steel .. the yeild and the expansion, it seemed that 7075 was

overkill anyway. But, I used 3/4 thick 6061-T6 - just in case.

Here is the drivers side bracket mounted on the spindle :

Using 3/4 inch thick aluminum gave me the opportunity to create a grease cavity

in the back side of the bracket. This is something that Studebaker used at all four

corners of the car, it is there so that if a grease seal was to fail .. the grease will

ooze harmlessly out the back .. and not end up on the drum or disc.

Here is a view from further back, sorry about all the grime and crud, I wasnt in the

mood to clean any more then I have too to check fitment. Once I swap out the GT

rotor and caliper for the big Cobra stuff, I will scrape and paint everything.

Here is the hub back on, and as you can see, designed in the bracket inner dia lets

the hub sit inside of it ... so if the grease seal fails ...

Now on to the passenger side, a mirrored bracket :

The rotor and caliper mounted :

There they be! Ofcourse the next step is to attach the Mustang brake lines to the

Studebaker frame, and for that the factory Mustang brackets didnt work, and the

factory Studebaker ones didnt either. So ... time to cut and bend and weld!

Tom

-

Well ... here is the next step in the Mustang GT brake project : test bracket. Its

always best when prototyping, to test your dimensions before going to metal. I

used some masonite to fab a rough bracket and test the design.

Here is the test bracket mounted on the spindle :

The large radius is to clear the massive wheel cylinder on the front caliper.

Here is the modified Studebaker hub mounted on the spindle:

Then we slip the Mustang rotor over the studs (with the metric holes drilled to the

next size SAE : 5/8):

And finally test fit the caliper onto the bracket to see how we did:

Turned out that I got pretty close on my first try. The only drawback was the lower

caliper bolt is right in line with the steering arm on the spindle. Not really a HUGE

problem, there are some tools that will allow the torquing of the bottom bolt, its

just nice when everything clears perfectly. Other then that, all looked great, now

to mill some 6061-T6!

Tom

-

Paul and Leonard both quickly responded and sent me photocopies. While I offered to pay for copying charges and postage, both refused payment.

I OWE YOU, ALL WHO LOVE THIS CAR OWE YOU.

Its good when people that CAN help ...... DO help.

Tom

-

I think Myers Studebaker has the adapter available for the GM auto tranny:

Unfortunately the automatic adapters will not work with the heavy flywheel, I have

the one made by SteelTech, and Dave warned that he would NOT trust it with a

manual trans. Trust me, I went through that process. Since the explosive damage

that would result from a flywheel that came loose from the crank, its best to not

use ANY type of adapter between the crank and the manual trans flywheel. I got

over 20k on the SteelTech adapter with a 700 trans with no issues. I sold it to my

brother in Michigan to put into his 64 Lark Daytona.

Tom

-

Since the vintage radio guy who advertises in TW (and a period Avanti options brochure) says an AM/FM was not a factory option in '63, I was wobndering about a period aftermarket radio.

My 1963 has an AM/FM in it that works. I will be ditching it for an MP3 playing

blah blah newer type unit. It works, looks old, never bothered to see what it

was. You interested in it?

Tom

-

Also, is there a current interchange available for the 3/4" rear wheel cylinders? Any brand and the part number would be appreciated. Thanks, John in Wisconsin

I dont believe so, but there are some outfits that sell sleeved ones.

Tom

-

Be aware that R134a is not compatible with the OEM oil that is in a R12 system, could cause problems later on. A/C system should be flushed and oil for a R134a system added.

I remember reading that way back, and then they changed it recently saying that

it really didnt matter. I dunno. This kit comes with even 'specialer' oil to help with

the conversion. Cool stuff!

Tom

-

I read on another forum that McCloud? I think, was tooling up to make a bellhousing for studebaker V8's to adapt modern transmissions like the T5 & T56.

McLeod. I contacted them over two years ago through their website. Weeks went

by without hearing anything back, so I sent again, thinking that perhaps their

system was down. Finally in ONE day Red (the owner) replied to ALL the emails

in one day. This was over a MONTH later. His first email was not very helpful

but with inquiry about what I wanted. The second was frustration and the third

was asking my why I was harrassing him. Obviously not a very bright guy. The

emails would have had DATES on them showing they had been sent over a spread

of a month or so. I attempted to explain it to him, but was like communicating

with a tater tot. He told me that he would look into it and get back to me. Two

years later I have heard NOTHING. I am currently talking to Fairborn Studebaker,

www.fairbornstudebaker.com about a special flywheel since they make aluminum

flywheels. Dave Levesque of SteelTech was also very helpful, but doenst make

any flywheel parts (though he does offer an adapter for the 700 Autos). All the

nice writeups in the car magazines like Popular Hot Rodding that mention McLeod

say that they are a great outfit, but they are obviously not interested in helping

the Studebaker community! Dealing with them was almost as bad as this guy

Bob Bendtsen, who also makes an adapter. He's absolutely terrible to deal with.

I am tempted to post the Email conversations with him here, just to keep all you

good folks from having to go through that. His "kit" doesnt allow the use of the

hydraulic clutch assembly, and requires dumping all the parts associated with it

and only using the trans itself. This is not good since part of the draw of the T56

IS the easy to push clutch. Its also more simple to mount (no alignment problems)

but when I asked him if his kit could be modified to use the hydrulic clutch, he said

I had a BIG ego?!?!?!?! Anyway .. steer clear of him, obviously he isnt getting all

that many takers on his "kit". Oh, he also told me that it was stupid of me to have

bought the entire T56 trans assembly without having an adapter first. But I tried

to explain to him that ANYONE that buys a used T56 from a partcar is GOING to get

the WHOLE deal, from flywheel to tailshaft ... hell if I was selling one, thats how I

would sell it!! What good is a T56 bellhousing, clutch, pressure plate, and cylinder

if you dont have the trans?!!?

I explained that selling in a nitch market, he should really strive to work with the

customer and not name call and talk down too .. he said it wasnt Burger King.

When I said I would design my own (this is the best part) he said,

"Good luck designing anything. It doesn't sound like you know enough. 35 years old? You're still in diapers. Talked down to? I haven't even started. I've been holding back. Maybe someday you'll be smart enough to manufacture specialty items and deserve your big ego. Not now though sonny."

Talk about a chip on the shoulder huh?? Oh .. BTW .. the rear disc brake brackets

are now machined and fitment will happen tomorrow. I already designed and had

machined the front caliper brackets and the brakes are on the Avanti and working

QUITE nicely now. The rear disc brakes should be working tomorrow. After I have

the rears done, then I will look toward swaping the GT brakes for 13 inch Cobra

brakes ... since as I said they use the same mounting bracket and the Stude hubs

I modified will accept the rotors. I wonder if there is a market for this? These

will accept ANY brakes available for 1994 thru 2004 Mustangs, which includes all

the Baer, Hawk, Brembo, StopTech, Wilwood and probably many others.

Not smart enough Bendtsen? Hmmmmm.

Tom

-

1) Take your Avanti to an A/C shop and have the leak fixed and convert it over to R134a. Will be cheaper in the long run. Installing a different system is not cheap or easy.

I will be using the NAPA R134 upgrade kit on my wifes 1986 IROC soon. Its not

that expensive and comes with all the fittings. I think it was 65 bucks? Chances

are your R12 system is leaking from the actual shrader valves, I had this happen

on my 1993 Camaro Z28. Its an R134 system ... but those valves go bad.

Tom

-

Wow Tom, at 25 mpg I gotta believe that 700r4 would be a good investment with gas moving back up towards 3 bucks a gallon. Would that trans hook up to the stock shifter, or what are guys using in this conversion?

Chris

My dad just installed that same 700 R4 into his 1969 Avanti, of course he didnt

need the adapter since it has a GM engine. I think he used the stock shifter, but

its only got 1 2 and 3 .. where as the 700 has 1 2 3 and OD. I used a B&M in

the Hawk, but then it had no floor shifter. I would assume with some creativity,

you could use different length arms on the trans to make use of the whole swing

of the shifter. Then you would need a new selector place made up to show what

gear you are in. As previously mention elsewhere, my Avanti's 3 spd stick is

going to be replaced with a T56 6 spd, once I figure out the details. Thats got

TWO over drives! Should get close to 30 mpg in an Avanti.

Tom

-

With a "built" Studebaker engine, and a 700-R4 trans in my Hawk, I would get

around 25 mpg on the freeway. Avantis are not really "light", weighing in at

over 3400 pounds, my Hawk would have been about 3000 for the coupe.

Tom

-

If you look down from the top the upper hinge is flatter with less of a bend then the lower hinge.

Maybe he can remove the hinge from the car, and bend the arms back with a 10

ton press, if it bent once, it will bend back. Heat might make it brittle.

Tom

-

My body guy told me that my driver's side upper door hinge is bent and that is why the door can't be adjusted flush. Does anyone know where I can get a door hinge for my '87?

Thanks.

I dont understand how a door hinge can be "bent". Its possible that the hinge has

sagged but doubtful that its bent, was the car in an accident? If its still and Avanti

hinge (read 'Studebaker') then it shouldnt be bent. If its a GM style hinge, then

it probably needs a new "pin". Most "HELP!" sections at auto parts stores carry

these GM replacement pins.

Also ... he SHOULD be able to slot the holes in the hinge if you can not find a new

one somewhere.

Tom

-

Sent you an email.

Received your email ... replied by email to your email that you emailed me.

Tom

Wheels and tires

in 1984-91 Avanti

Posted

Yes .. that does make it easier to find stuff, but I find it strange how you have less rear

wheel room then the Lark-chassis cars. Weird.

Tom